Our high performance industrial non-metallic gasket material sheets – Compressed Non-Asbestos (CNA) contains high-pressure and high-temperature aramid fiber materials that are perfect for sealing, thermal, and mechanical applications (petrochemical, chemical, steam, pulp & paper, pharmaceutical and potable water industries).

Durlon® Compressed Non-Asbestos (CNA) products range from purely economical to premium grades with a variety of synthetic fibre reinforcement and rubber binder systems to meet the majority of general service industrial piping applications. Durlon® CNA products are the only products in its class to be manufactured in Canada and have been since the early 1980’s. Explore our CNA product styles for the one to meet your application requirements.

Many gasket users have encountered problems with various compositions associated with flange adhesion for years.

Apart from the separation of flanges, surface imperfections can result from careless gasket removal. After time, under load at elevated temperatures and pressures, there is a tendency for gasket materials to become embedded in the flange on opening, or sometimes disintegrate and pieces stick to both flange mating surfaces resulting in a problem when removing the adhering gasket material in a safe and timely manner and without damaging the flanges. Many times, wire brushing or wire wheels is a common practice, but if not done properly can lead to damaged process equipment or system contamination.

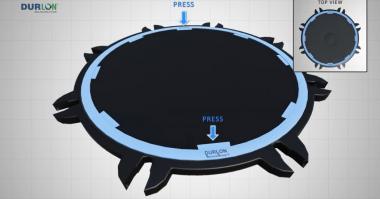

To overcome this problem, anti-stick technology has been incorporated into the manufacturing process of the compressed non-asbestos (CNA) DURLON® products. This anti-stick technology allows for improved separation from flange surfaces during removal, saving time and energy, and all without compromising the performance of the gasket.

This new technology allows DURLON®(CNA) to be the best in the industry; gasket and sheet materials have passed the MIL-G-24696 Navy Adhesion Test (366°F/48hrs).

Military Adhesion Mil-G-24696

Adhesion Comparison between gaskets produced without anti-stick and with anti-stick.

Sample size: 1.25” X 2.0” X 1/16” Platens: Carbon steel and Stainless Steel

Conditioned samples are installed between two platens and torqued down to 30 ft-lb.

The platens are placed in an oven for 48 hours at 185ºC (366ºF).

Cold platens are separated and rated according to the following:

- Gasket can be removed cleanly with virtually no residual material remaining.

- Only a small amount of face material remains when gasket is separated from platen.

- Can be removed in one piece but some body material remains on platen.

- Can be removed in one piece but a considerable amount of body material remains.

- Cannot be removed in one piece and delaminates upon removal.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments