Variable Speed Drive technology has been around for many years. The question is, when should VSD technology be applied and what is the best methodology for controlling the speed of the pump.

Adjustment of the pump speed is an efficient way of responding to fluctuations in flow and pressure demand in the system, particularly if the system in question is dominated by friction head. Variable speed drives enable a higher degree of control on the pump speed – adjusting the speed of a single-speed motor to precise levels over a wide range by electrical and mechanical methods. However, there is a misunderstanding within the industrial sector that VSDs are considered practical for situations where the demand changes continuously and with varying increments the sole intent being reducing energy consumption again in a friction dominated system.

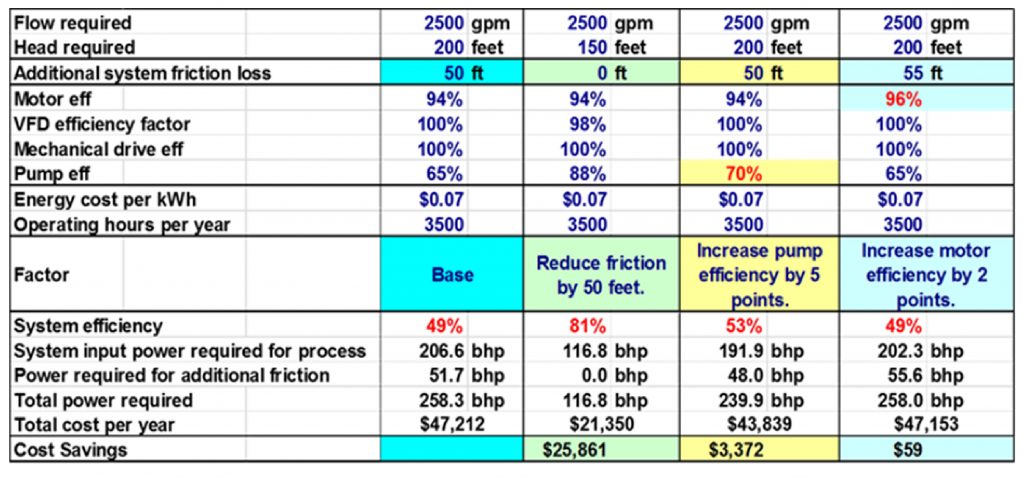

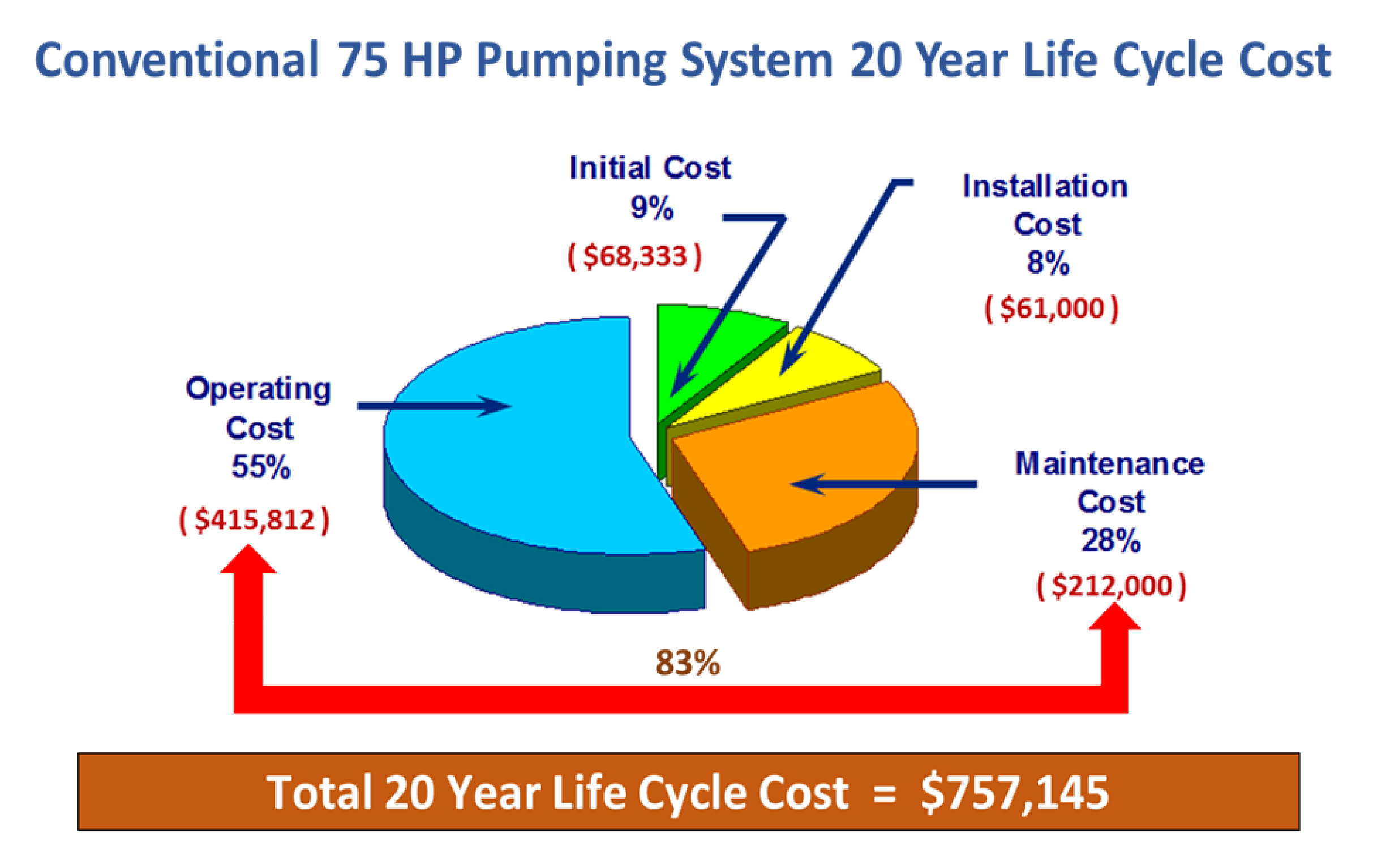

There is more to the story than reducing energy consumption, consider total system efficiency, reliability, reduced maintenance cost and life cycle costing as well as choosing the appropriate speed control method.

Dynamatic will be sponsoring a 1-hour webinar that addresses all these issues as well as choosing the appropriate speed control methodology. Variable Frequency Drives have become the speed control solution of choice over the last decade. But is it the best choice? Not necessarily.

Register for this informative webinar “The Evolution of Variable Speed Drives in the Pump Industry” available on-demand, to gain insight on the history of VSD technology, choices available, and where the various technologies are the most cost-effective.

DSI/Dynamatic will also share Excel spreadsheet-based tools for all registered guests.

Watch this webinar on-demand Click Here.

Comments