Contributor: EBARA Pumps Americas Corporation

FOG (Fats, Oils & Grease) and Scum (Figure 1) can be found in many areas of today’s wastewater treatment. The most common areas would be lift stations, clarifiers and septage/FOG receiving stations.

FOG and Scum can create some unique pumping challenges. If not handled properly, it can create large floating mats reducing wet well volumes, clog pumps and piping, and could result in an overflow/spill or environmental hazard.

FOG and Scum typically have a specific gravity of <1, causing it to decant from water and float on the surface. If allowed, this decanting will form large floating mats that will accumulate over time. The simple pumping operation of a wet well will also create this mat. As the pump cycles from on/off, it is merely dewatering the form under the floating mat. This mat will thicken with each pumping cycle and reduce the liquid volume of the wet well.

Eventually, the mat will congeal and solidify. This requires manual removal with a vacuum truck or other solids handling equipment. FOG/Scum may also cause problems with float switches or other level controls, requiring free movement or stable wet well hydraulics.

When pumping wastewater with FOG and Scum, it is important to keep things turbulent and mixed within the wet well. It is also important that the pump head (volute/impeller) be submerged in the wet well. FOG/Scum has been known to plug suction lines, restricting the flow to dry well pumps and causing pre-mature pump failure.

A submersible pump with a mixing nozzle is ideal to help keep the wet well homogenized and free of any FOG/Scum buildup. A submersible pump having the impeller and volute submerged will also eliminate any suction line blockages.

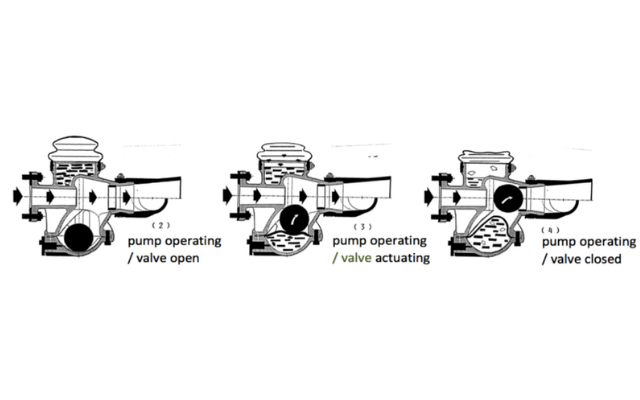

A submersible pump with a mix/flush valve is an ideal solution for pumping wet wells containing FOG/Scum (Figure 3). The hydraulic mixing action created by the mix/flush valve keeps the solids in suspension during the pumping cycle, reducing the accumulation that can form a floating mat. This system is completely automatic and requires no additional hardware or electrical apparatuses installed within the wet well.

The pump and mixing/flush valve are all one unit mounted on a standard or non-sparking guide rail system for easy removal during scheduled maintenance.

FOG and Scum handling will always be a challenging process during treatment and disposal, so keep your head in it, mix it up and avoid the mats.

Rhonda LaFrance and Pete Curcio Joins EBARA Pumps Americas Corporation

Comments