When: November 6 – 7, 2018

Where: Houston, Texas (Click here for the Webinar or learn about on-site training at your facility)

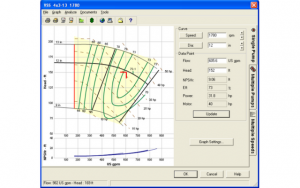

FLO-Master Training provides attendees with a detailed understanding of how to model piping systems using PIPE-FLO® Professional. By learning the key elements involved in simulating the behavior and interaction of pipelines, pumps, components and controls throughout the system, participants will gain a greater knowledge of piping system devices and how they work together as a complete system.

During the FLO-Master Training, instructors demonstrate a comprehensive step-by-step approach to using PIPE-FLO® which covers features, tips, and tools that are not available through the basic program tutorial.

After attending a FLO-Master Training session, attendees will be able to build PIPE-FLO® system models faster, tackle the most complex fluid piping projects, and create and optimize piping systems for efficient operation, maintenance and use of capital.

Who should attend?

FLO-Master Trainings are ideal for those using the PIPE-FLO® Professional program to design, build, operate, and maintain fluid piping systems. Both new and experienced PIPE-FLO® Professional users will gain from this class because it covers everything from piping system operation to a comprehensive exploration of the PIPE-FLO® software.

Course Objectives

Attendees will learn how to:

- Build a PIPE-FLO® Professional piping system model in less time

- Use fluid flow theory to gain an understanding of the total piping system

- Maximize the use of PIPE-FLO® Professional’s program features and increase productivity while decreasing capital, maintenance, and operating costs

Course Topics

- PIPE-FLO® Professional User Interface

- Building a Piping System Model

- Calculations

- Model Validation

- Using Lineups to Model Different Operating Scenarios

- Modeling Engineering Designs and System Modifications

- Importing and Exporting Piping System Data

- Designing Modifications and Troubleshooting Piping Systems

Comments