Motors controlled with variable frequency drives (VFDs) can be at risk of electrical bearing damage. VFDs can induce harmful voltages on motor shafts; voltages that can destroy bearings and dramatically shorten motor lives.

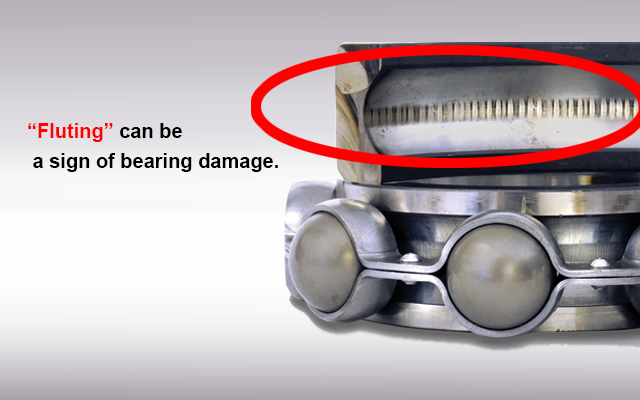

Without effective bearing protection, these voltages can discharge through motor bearings, causing electrical discharge machining such as pitting (fusion craters in bearing surfaces), frosting (widespread pitting), fluting (washboard-like ridges in the bearing race), and complete bearing failure – often in as little as 3 months!

Are your motors at risk? How can you check?

Typically, motors at risk of electrical bearing damage generate wave forms with repeated voltage buildups and sudden discharges. Motors protected with bearing rings, on the other hand, produce flat waveforms, indicating continuous discharge through the ring instead of through the bearing.

There are two main ways to check for bearing damage from induced shaft currents — measuring vibration and measuring voltage. Both require special equipment. But while vibration testing can detect bearing damage only after it has occurred, shaft voltage testing can predict bearing damage before it occurs, allowing motor users to take preventive action.

By the time vibration testing confirms bearing damage, the damage has usually reached the “fluting” stage (shown in the image above). But shaft voltage testing can determine if the cause of electrical bearing damage is present, so users can protect motors from damage by installing bearing rings before such damage occurs.

DOWNLOAD OUR FREE HANDBOOK: Best Practices for Bearing Protection

DOWNLOAD OUR FREE HANDBOOK: Best Practices for Bearing Protection

Our 56-page handbook describes the causes and symptoms of VFD-induced bearing damage and shares best practices for protecting motors against VFD-induced bearing damage.

Comments