We would all agree that Albert Einstein was a bright guy. So we should take heed of a simple quote he made about “insanity”, which was, “doing the same thing over and over again and expecting different results.” While this quote usually relates to human behavior, it may also be applied to pump engineering. Simply applying existing and usual engineering approaches to developing a new product often returns us to old and recycled ideas with similar, if incrementally better results. “Expecting a different result” was the guiding mantra behind the new and truly revolutionary TORNADO® T2 rotary lobe pump from NETZSCH Pumps and Systems.

Rethinking the Rotary Lobe Pump

With over a 130 year history of engineering innovation and discipline, NETZSCH challenged the current state-of-the-art rotary lobe pump design and pushed it into a new paradigm that challenged conventional wisdom. In redesigning the TORNADO® T2 rotary lobe pump, the voice of the customer was critical. Customer “pain points”, relating to reliability, maintenance, performance and total cost of ownership informed the thinking of NETZSCH design engineers.

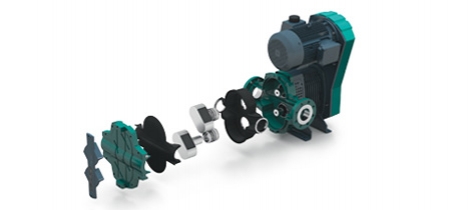

Traditional rotary lobe pumps employ two rubber-covered lobes that rotate inside a metal housing, often with bolted-in metal wear liners. In fact, NETZSCH used this approach in its original TORNADO® (T1) Rotary Lobe Pump. This was the first conventional standard that the NETZSCH design team tackled. In conjunction with a team of engineers at a well-known German engineering institute, the question was asked, “Why not reverse the construction of a rotary lobe pump by making the lobes in steel and the housing in rubber?” The result of this contradictory thinking is at the center of the new TORNADO® T2, with lobes running inside a metal housing with an elastomer liner. The concept of combining the wear resistance and simple metal-rotor/rubber-stator construction of a progressing cavity pump with traditional rotary lobe pump technology establishes a remarkable engineering development for the TORNADO® T2. This design breakthrough does not require o-rings or gaskets and creates the advantage of durable and robust construction along with simplicity and ease of maintenance.

Reaching Outside the Pump Industry for Innovation

For more than fifty years it was common knowledge that a rotary lobe pump could not be built without a set of timing gears. The TORNADO® T2 pump pushes this concept into the past by employing a single, synchronous toothed timing belt. By using technology common to the automotive industry, the maintenance-intensive and costly gearbox has been eliminated.

Next on the list for NETZSCH engineers was a solution for minimizing the problem of pulsation while still using durable and simple bi-lobe rotors that are better for solids handling. A unique pulsation reduction system (PRS) employs channels molded into the rubber walls of the pumping element that release the lobe energy and dampen pulsation. This is the equivalent of using a quad lobe rotor, meeting customer demands for shear sensitive product conveyance and no pulsation downstream.

Design Reduces Maintenance and Downtime Exposure

The design of the pump housing includes integrally cast round flanges – the only one of its kind in the industry. This unique housing design feature provides for easier joining to round piping as well as maintenance benefits. Having full flange-to-flange access when servicing the pump offers maintenance personnel more room to access pump internals without the need to disassemble piping. A unique seal design greatly reduces the chance of leaks and catastrophic pump failure.

Full “service-in-place” was engineered into the TORNADO® T2, thereby supplying easy access to the mechanical seals, rotors, liners, as well as for timing the lobes. According to Julio Ferreira, Vice President of Sales for NETZSCH Pumps North America, “Our engineers designed a tool that we include with the TORNADO® T2 that will radially and axially align the lobes to set the timing of the pump in less time than it takes to look for the wrenches and screwdrivers to work on conventional lobe pump with timing gearboxes.” With a little experience, full pump assembly or disassembly can be accomplished in under 15 minutes.

The single timing belt drive, which eliminates the need for a second reduction component to the pump assembly also reduces a host of maintenance issues. There is no oil to replace or maintain and there are no timing gears to fail, significantly lessening the chance of a pump replacement. In fact, NETZSCH does not consider the timing belt to be a wear-part; having undergone intensive testing of 10,000,000 starts and stop cycles.

About NETZSCH:

Within the Business Unit Pumps & Systems which offers the NEMO® progressing cavity pumps, the TORNADO® rotary lobe pumps, macerators, dosing systems and accessories, NETZSCH has been offering tailor-made and sophisticated solutions for applications in many industrial branches for more than five decades on a global level. With more than 2,500 employees, the Business Unit “Pumps & Systems” is the largest business unit with the highest sales of the entire NETZSCH group.

The NETZSCH Group is a globally active, family-owned enterprise headquartered in the Bavarian town of Selb, Germany. Our international presence is backed by 130 sales and production centers in 23 countries on three continents.

Our three business units, Analyzing & Testing, Grinding & Dispersing, and Pumps & Systems, are independent organizations acting with the objective of offering each and every customer the very best solution for their individual requirements.

Contact:

NETZSCH Pumps North America, LLC

119 Pickering Way

Exton, PA 19341

USA

Tel.: 1-610-363-8010

Fax: 1-610-363-0971

npa@netzsch.com

www.netzschusa.com

Comments