Several months ago, HOMA was asked by our distributor Emmons Metro to provide a solution to a critical station at a facility that handles wastewater from produce and associated packaging for a large supermarket chain in the Northeast. The existing pumps were a cutter / chopper type pump from a reputable competitor. These pumps were struggling to pass the solids content found in the wastewater and were clogging regularly. The solids were primarily long and fibrous plant matter that was forming rag balls around the cutter blade. This meant near weekly callouts at substantial cost.

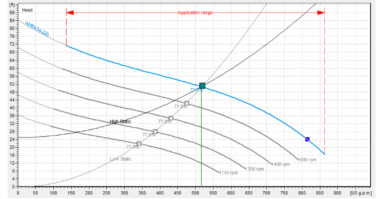

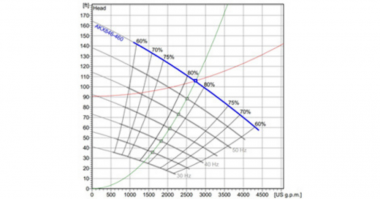

Instead of retrofitting the application with another grinder pump, our application engineers decided that with its large, smooth, solids passages, the HOMA AMS series, single vane, non-clog pump would be able to more effectively handle the solids in the waste stream.

With that in mind, our application engineer selected an AMS334-160/4.3T/C, 4.3hp pump. The volute flange was machined to accept the bolt pattern of the existing competitor’s guide claw. The original guide claw was fitted to the new pump, and it was installed onto the competitor’s existing rail system base. The new HOMA pump was able to be wired into the existing control panel and reuse the competitor’s seal leak and thermal sensor relay.

After six weeks of operation, HOMA received the below comments from Emmons Metro regarding the application:

Gentlemen,

I want to thank you guys for helping us out with this problematic station. I believe this was an excellent test for the AMS impeller and it is proving itself to be extremely effective thus far. We went out to the station today to do a checkup because they haven’t had any alarms go off since the AMS pump was installed, which was about 5 weeks ago. Ran through all electrical readings and pulled both the HOMA pump and the [XXXXX] pump out of the pit to do physical inspections. Our findings are pretty substantial (and I am glad we went today because they would have been in a lag/alarm scenario next week). See attached pictures … They speak for themselves.

Ultimately, we have provided our customer with the correct pump for the application and I foresee another pump going in within a couple of months. That [XXXXX] pump is going to die at some point in the near future. We will be using these pictures as evidence to assist in specifying the pumps as well.

Thanks again for all your help!

When retrofitting a problem station, replacing like-for-like is almost always a recipe for continued issues. It is important to evaluate why the station is problematic and find the best approach to solving the root cause. In this application, switching from a grinding/cutting solution to a pump with superior solids handling has helped save time and, more importantly, money for the customer.

Emmons Metro LLC is a distributor of water and wastewater pumps, controls, accessories along with complete system solutions and field and shop repair services. For additional information, please contact them at:

Emmons Metro LLC

453 N. Pearl Street

Albany, NY 12204

Tel: 518-694-0404

e-mail: info@emmonspump.com

website: www.emmonspump.com

Comments