Efficiency is one of the most important metrics in the modern pumping world. Being able to do more with less is critically important whenever money is on the line, and in the pumping world, that is most often measured through operating costs. However, it is important to remember that efficiency comes in many forms, not just the “clean water efficiency” shown on pump curves. We will go over some of the best practices to ensure overall station reliability, i.e., “total station efficiency” in order to keep operating costs and downtime at a minimum.

The most important step towards maximizing the efficiency of a station is making sure that the pumps are running. The efficiency of a clogged pump is zero, so it is critically important that a station has a minimum of downtime to avoid expensive callouts or costly bypass pumping. This can be accomplished by using pumps designed for handling the types of solids that will expected in the pumped media. For example, if the media contains a large amount of stringy solids and rags, it would be beneficial to look for an impeller design that can handle that sort of material, even at the cost of several points of published efficiency. This could mean a pump with larger solids passages, a vortex-style impeller, or even a grinder/shredder pump. Even with a modestly-sized pump in the 30hp range, the costs of a callout can dwarf the operational savings from the incremental “paper” efficiency gains which are based on pumping clean water, not wastewater. As soon as solids and rags enter the stream, that curve may change drastically.

Let’s examine an example case: at the current national average cost of power of $0.10/kWh, with a pump operating on a 30% duty cycle, and an operating point of 800 GPM at 80ft TDH, a drop in hydraulic efficiency from 80% to 70% yields a cost of approximately $730. Measured against the cost of a nuisance callout, it may make more sense to opt for a slightly less efficient impeller that is designed for the task.

This tradeoff is diminished at lower horsepower ranges and magnified at higher horsepower. With the same parameters and an operating point of 400 GPM at 40ft TDH, the same drop in efficiency costs only $182, while at 2000 GPM at 150ft TDH the equivalent drop costs $3423. With that in mind, in lower horsepower applications, it often makes more sense to make more dramatic compromises in hydraulic efficiency for the sake of clog-resistance, and in higher horsepower applications it becomes more important to proactively design the station to mitigate these issues.

So how does one design a station to better resist clogging? Some examples of best practices include proper use of bar screens to prevent the largest solids from entering the well, chamfering the floor of the well to prevent inlet-restricting sedimentation from building up in low-flow scenarios, installing discharge-side vacuum release valves on the pump side of the check valve, and locating the check valve at a high enough elevation to allow for backflushing of the pump when the pump is shut off, and ensuring sufficient velocity in the suction piping to prevent sedimentation and buildup. These are only a few examples, and for an adequately-sized pump station it is critical to consult with a qualified design engineer to ensure the best results. A little extra effort in the design stage can prevent many years of headaches in the future.

Preventing downtime is one of the primary factors in maximizing the lifecycle efficiency of a station, but there are other elements to look at in order to ensure a station is operating at maximum efficiency. The operation of the pumps should also be accounted for, and whether the pumps will be controlled with a variable frequency drive (VFD) or simple on/off regulation. Each can be effective and depending on the operational realities of the installation, one or the other may result in more efficient performance, so it is important to examine the data to determine the right choice.

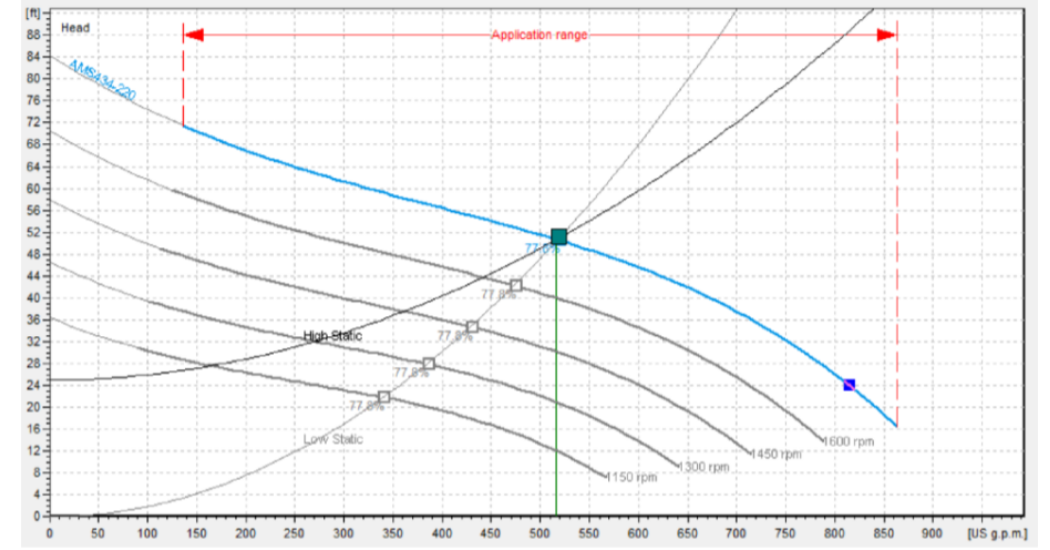

Broadly speaking, installations with high static head, and a relatively small component of velocity head (common in lift stations with short force mains) tend to operate more efficiently with on/off regulation, and installations with low static head and a high component of velocity head can operate more efficiently with VFD operation. The performance chart shown above illustrates how different types of system curves impact pump performance when operated on a VFD. Both system curves with low static head and with high static head are operating at the Best Efficiency Point (BEP) on a full speed performance curve. As the speed decreases, the low static head system remains operating at BEP, but the high static head curve moves progressively to the left of the curve and into an area of lower efficiency.

It is also important to remember that these savings operate on the same sliding scale as those of hydraulic efficiency. That is to say that below a certain horsepower there are diminishing returns to investing in a VFD, controls, and design to save a relatively small amount of money. On the other hand, when designing a large station where a few percent efficiency can save thousands of dollars, it is critical to put in the requisite engineering research to ensure the best performance possible.

Another often-overlooked factor in lifecycle cost of a pump is the cost of maintenance, both routine and unexpected. Earlier we examined the issue of unplanned pump downtime, but routine downtime can be just as costly. It is important to account for the scheduled downtime of equipment that requires frequent, routine maintenance and what the labor requirements are to perform this. Additionally, wear parts must be replaced over time and the price of these parts must be factored in, especially if these are proprietary parts. Some pump designs feature more wear components than others, and at higher costs, so it is important to include these in lifecycle cost calculations. Consider seeking out spare part pricing during quotations, but remember that the spare parts quoted with a pump will be significantly cheaper than those purchased separately in the future. It may be worth questioning the supplier on the typical pricing for these components when sold as individual components as opposed to as part of the project price, or discussing a parts pricing contract.

Lifecycle costs of operating a pump station can far outstrip the upfront price of the pump, so it is critical to put in the due diligence up front to ensure the lowest lifetime cost. Many of these are “hidden” costs that are not always considered when designing a station, but by evaluating many aspects of a pump’s lifecycle and taking a proactive approach to designing around best practices, you can be assured you will get the most bang for your buck.

Comments