Open impellers are frequently used in centrifugal pumps, which pump liquids that contain suspended solid materials (slurries, paper stock, etc.). They do not plug as easily as closed impellers and usually have a simple external adjustment to maintain the correct impeller clearance as internal parts wear.

The front, or suction side, of the vanes must be set with a close clearance against the suction wear plate to achieve high efficiency and good performance. As the impeller and suction plate wear, performance will deteriorate over time. Regular clearance checks and adjustments will maintain good performance.

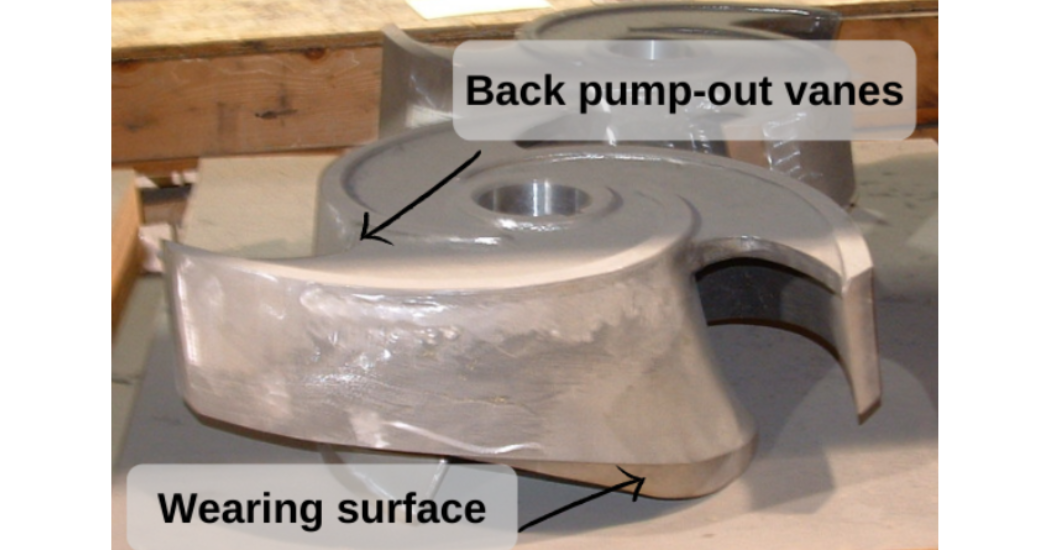

However, as the impeller is adjusted toward the suction wear plate, the clearance behind the impeller increases. Most open impellers have small vanes on the non-pumping side, called “back pump-out vanes”. These vanes act like another centrifugal pump and have the purpose of maintaining a low pressure at the stuffing box. Without these vanes, the stuffing box pressure would be close to the discharge pressure of the pump, which could result in contamination of the packing and low packing life.

So if reduced pump performance suggests that the impeller clearance be adjusted or if packing life is reduced, both the suction- and back-side clearances should be checked. If the back-side clearance exceeds the manufacturer’s recommendation, then a thinner gasket should be installed between the pump volute and the stuffing box cover so that correct clearance can be achieved.

Just as the suction-side clearance must be maintained for good pumping performance, the back-side clearance must be maintained for long packing life.

For more essential care and condition monitoring tips, buy IDCON’s 4 book series “Condition Monitoring Standards”

Comments