Overview

In this Kansas minimum / medium-security prison, items such as cloth, plastic bags, paper, feminine products, and even needles are often flushed down the toilet, wreaking havoc on the original pumping system, causing headaches for the maintenance teams.

The prison’s greatest concern is the potential for a clogged pump to cause unscreened sewage to back up into the prison block. This would require moving hundreds of inmates to another location to properly clean and sanitize. Not only is this logistically difficult, but the time and expense would be painstaking.

The original “non-clog” submersible pumps were anything but that. At least 3 times per week, the maintenance team had to make the trip out to the pump station. The 48-inch diameter wet well made for a claustrophobic and hazardous climb down 26 feet to the pumps.

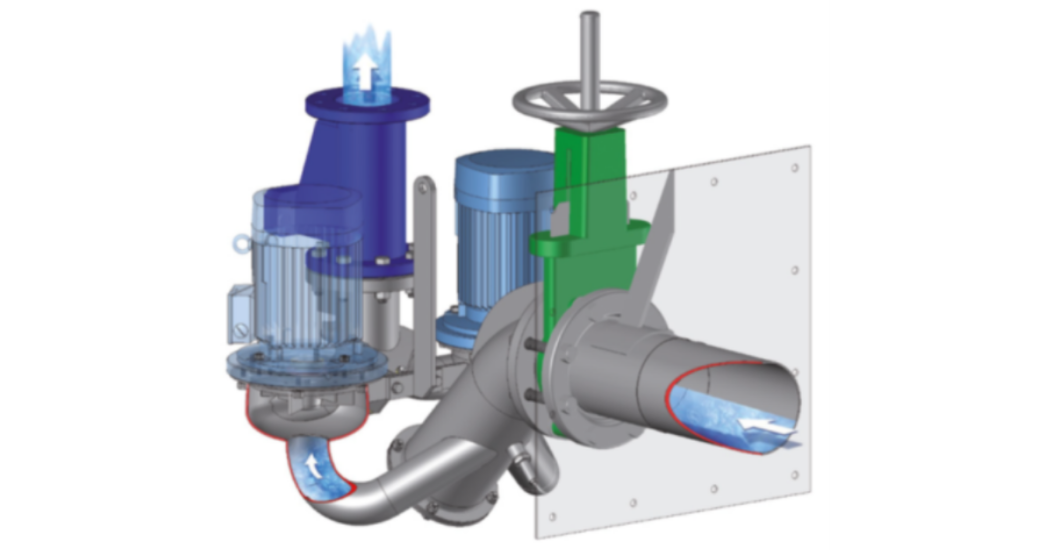

The facility wanted to upgrade the entire pumping station. An OverWatch™ Direct In-Line Pumping system was installed. This complete system including the duplex OW101-6VV 5HP stainless steel pumps and valves were pre-installed into the new dry well, along with a plug-in-ready control panel. The entire tank was lowered into place, connected to the inlet and discharge, and was online pumping in just a few short days.

The pumps were installed with the patented DIPCut® impeller, allowing the pumps to reverse rotation and shred potential clogs when the smart-sense VFDs sense an increase in torque. This has allowed the facility to eliminate those frequent trips to the wet well.

Eliminating the wet well to maximize safety; minimize maintenance

The OverWatch™ Direct In-line Pumping Technology creates an environment that eliminates wet well maintenance, exposure to dangerous gases, and hazards associates with retained effluent, while saving 30% on energy costs and 65% total savings over the life of the pump. Lifting liquid as it arrives removes the opportunity for whip, fats, oils, or greases to build up and solidify. The VFD-controlled pump allows the system to adjust its performance in real-time; reversing operation to remove clogs. With over 2000 installations globally, OverWatch™ is maximizing safety and minimizing risk by retrofitting current lift stations all over the world.

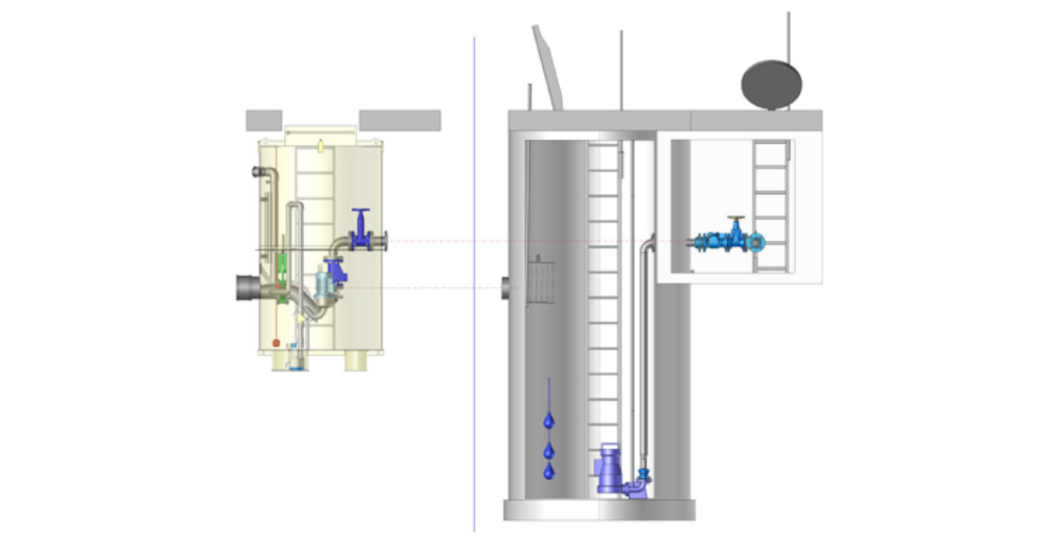

Direct In-Line vs. Traditional Installation

Benefits

- Eliminates the wet well and hazards associated with them

- Constant self-monitoring operation allows the system to adapt real-time to the environment, adjusting motor performance to the incoming flow and eliminating potential clogs without human intervention

- Reduced maintenance; no screen or well cleaning; no scheduled site visits.

Applications

- Municipal retrofits or new wet wells

- Residential, commercial, or industrial ejector pumps

- In-line pipe booster systems

Features

- Immersible IP67 IE3 Motors

- Modulated pumping driven by variable speed drives for optimized performance and savings

- Optional DIPCut®

- Shredding impeller for self-cleaning operation Shared stainless steel hydraulic body

- Isolation valve for easy maintenance

- Stainless Steel wall flange supplied for easy mounting

- Optional remote monitoring allows for control anywhere

- Stainless Steel level pressure sensor

- Stone trap/Cleanout

Comments