Vertical Recycle Paper Pulper

Make: Voith

Industry: Pulp and Paper

Challenge

A paper recycling mill had a vertical pulper that was leaking continuously for years. Pulpers are notoriously difficult to seal due to extreme shaft movement along with abrasive materials in the tub. Multiple sealing solutions were attempted, including a variety of packing types, but none lasted more than 3 weeks. The leakage was causing housekeeping and safety issues and required constant oil changes in the gearbox below due to water ingress.

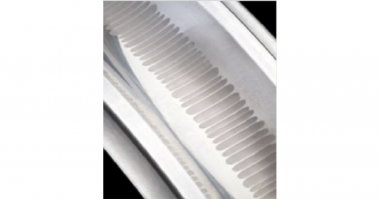

After: Pulper drive shaft with Inpro/Seal Air Mizer shaft seal in operation

Solution

An Inpro/Seal® Air Mizer® shaft seal was installed in April of 2016. The Air Mizer is a non-contacting, non-wearing shaft seal that utilizes a positive air purge to permanently protect against product loss and contamination. Its unique zero-maintenance design can fully articulate to handle angular, radial, and axial shaft movement simultaneously.

Inpro/Seal Air Mizer shaft seal

Result

After installation, the Air Mizer stopped all water and paper stock leakage from the pulper tub. The area below the pulper is now completely dry, making it safe for personnel to perform inspections and preventative maintenance checks. In addition, because there is no leakage, frequent gearbox oil changes have been eliminated.

Comments