Author: Mark A. Johnson

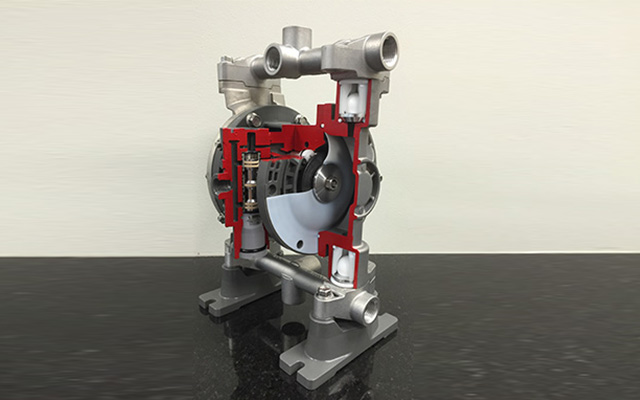

There is generally much confusion and misinformation about the differences between Cubic Feet per Minute (CFM), Standard Cubic Feet per Minute (SCFM) and Pounds per Square Inch (PSI), Pounds per Square Inch – Gauge (PSIG) when it applies to powering an AODD pump. Hopefully the information below will help you better understand the terminology.

In a future article, I will provide an overview of how to read and understand the different aspects of an AODD performance curve, and what air force (PSI) and air flow (SCFM) requirements are called out depending on your duty point – which is where Total Dynamic Head (TDH) and Fluid Flow requirements (GPM) intersect. As you can see, we love our pump acronyms, so I will start keeping a list and share later.

PSI/PSIG is technically defined as the pressure or intensity of air applied on one square inch on the surface of an object. For example, when you are pumping up a bicycle tire with a hand pump, it seems like it takes forever since the force of the air going into the tire is very low. There is more surface area on the inside of that tire, so it takes several pumps of air to fill. Theoretically, PSI is used to tell how full you can make that tire using the hand pump with no time limit.

CFM/SCFM is used to measure the volume/quantity of air flowing and technically called out as the amount of air within one cubic foot of volume. Back to the bicycle tire example above – if you were to use your handy-dandy garage air compressor which would provide much greater flow of air, the time to fill the tire is much faster because the volume of the air is much higher than you can produce with a handheld tire pump. Clear as mud, huh?

Rules of Thumb for CFM:

- For small garage-type air compressor, you will get ~2 CFM for every HP of the compressor

- For large industrial air compressors, you will ~ 3.5 CFM for every HP of the compressor

Learn more at www.iwakiair.com.

Comments