Contributor: John Crane

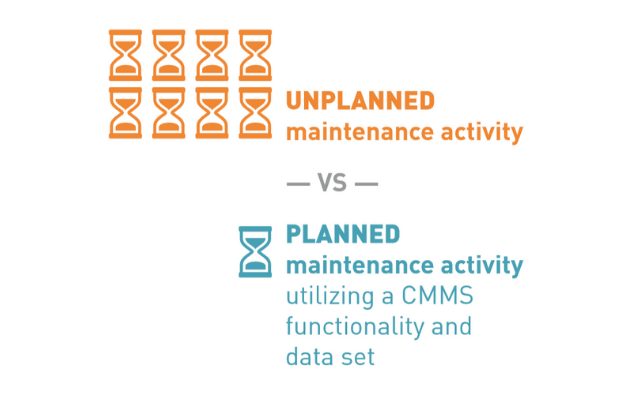

With a global increase in demand for energy, fuels, and chemicals, process industry businesses need to effectively maintain their assets to ensure consistent reliability and to meet challenging production targets. An increasing number of safety / environmental asset regulations challenging production targets and profitability goals pushes companies to implement a robust and effective CMMS – as the risk of noncompliance could potentially result in costly plant shutdown. In these instances, cost of unplanned maintenance significantly impacts operation and production targets. An effective CMMS enables informed decision-making by using a single data source as the baseline for maintenance practices. On average, an unplanned maintenance activity takes eight times longer than a planned maintenance activity, so using a CMMS can provide significant time savings, allowing for improved manpower levels and structured maintenance procedures to be put into place and ensuring critical assets receive the maintenance they require.

John Crane worked with a specialty chemicals company based in the United Kingdom. Their key goals were to control production costs, including maintenance, asset management and operating costs, in order to maintain a healthy bottom line. The company’s existing CMMS system had been out of date and unsupported, exposing the customer to many software issues and putting them at risk of decreased production and noncompliance of regulatory standards. Their CMMS did not meet the required standards needed to meet UK legal requirements to demonstrate assets were being adequately maintained.

The outdated nature of the CMMS caused problems when the customer upgraded to a new system, causing them to experience a troublesome implementation and data migration, eliminating their return on investment, keeping them from being able to use the upgraded system, and leaving them exposed to the same issues. Transitioning to a brand new and well supported CMMS would provide the functionality that would enable them to improve work practices, reduce maintenance costs, and decrease the risk of noncompliance.

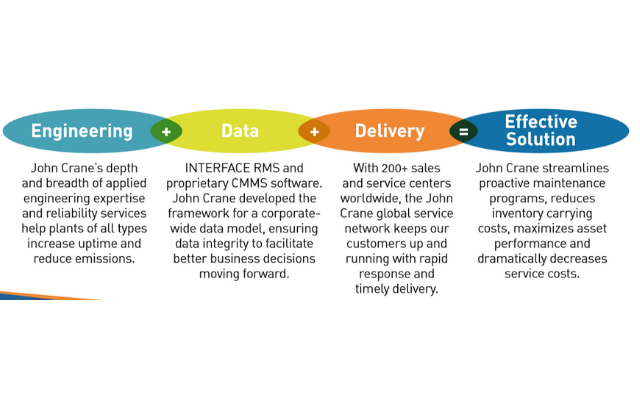

The John Crane Asset Management team consulted with the company personnel to undertake a high-level review of their data and practices. The data showed that there was no asset hierarchy and structure in place, meaning safety-critical assets were at risk of not receiving correct and preventive maintenance for improved performance. Thousands of assets in the plant had been missing in the original CMMS, highlighting a need to create thousands more preventative maintenance routines. Using John Crane Asset Management’s experience with data, engineering and project management, the John Crane team could uniquely analyze, scope, plan and price the solution that was needed.

The John Crane team is currently working to improve the data taken from the old system to complete a successful transition to the new CMMS. They will implement new business processes to manage the new CMMS and will review customer philosophies, strategies and methodologies. Ongoing support is being provided to the company, helping them create new business processes from data found and analysis undertaken on how to manage the new system.

The John Crane team is currently working to improve the data taken from the old system to complete a successful transition to the new CMMS. They will implement new business processes to manage the new CMMS and will review customer philosophies, strategies and methodologies. Ongoing support is being provided to the company, helping them create new business processes from data found and analysis undertaken on how to manage the new system.

By implementing the additional maintenance strategies and Preventative Maintenance Routines (PMRs), this company will significantly reduce their exposure to equipment failure and lost production. Implementation of John Crane Condition-Based Maintenance (CBM) strategies and services will result in less intrusive and more proactive maintenance, supporting improved equipment reliability and availability.

Comments