Metcar is excited to announce it’s M-310 nickel impregnated carbon graphite and M-161 babbitt impregnated carbon graphite materials will now be distributed globally by the Boulden Company. Boulden Company has decades of experience serving the pump repair industry. Their objective is to support plant engineers to improve the safety, reliability, and efficiency of their machines. The combination of Boulden Company‘s service-minded mission and Metcar’s high-performing materials will be a valuable asset to the pump repair industry.

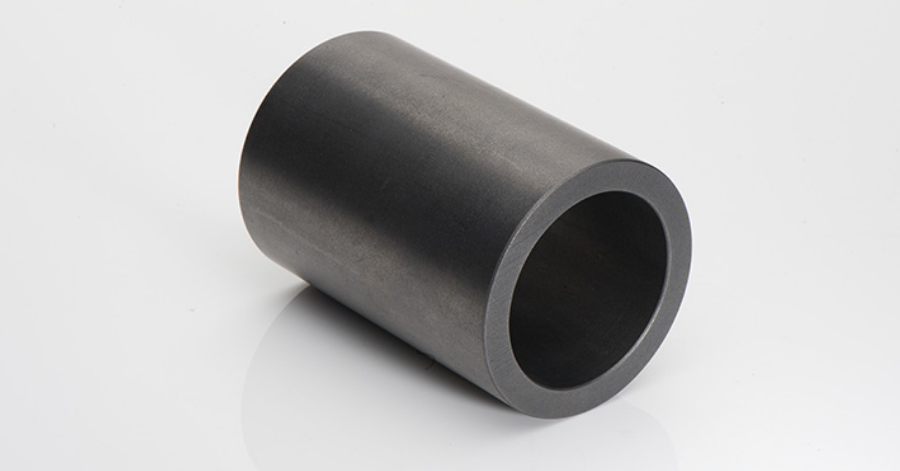

The M-161 and M-310 material grades are critical to the reliable operation of countless pumps in the utilities, oil & gas, and petrochemical industries. Carbon graphite is self-lubricating, so it can run dry in certain conditions without the need for grease or oil lubrication. Since there is no metallic attraction between carbon graphite and metal running surfaces, these M-161 and M-310 materials are not prone to galling or seizing, which is a known failure mode of other types of bearings.

Interested in these materials for your applications?

Metallized Carbon Corporation has been supplying engineered carbon/graphite solutions for severe service lubrication to industrial customers worldwide since 1945. Under the trade name Metcar®, our unique family of solid, oil-free, self-lubricating materials have been under continuous development by Metallized Carbon Corporation for over seventy years. With over seven decades of application engineering experience and field expertise, corporate headquarters and manufacturing facilities in New York, along with manufacturing facilities in Singapore and Mexico, Metcar is strategically situated to provide the global market with the materials it needs to keep the world running.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments