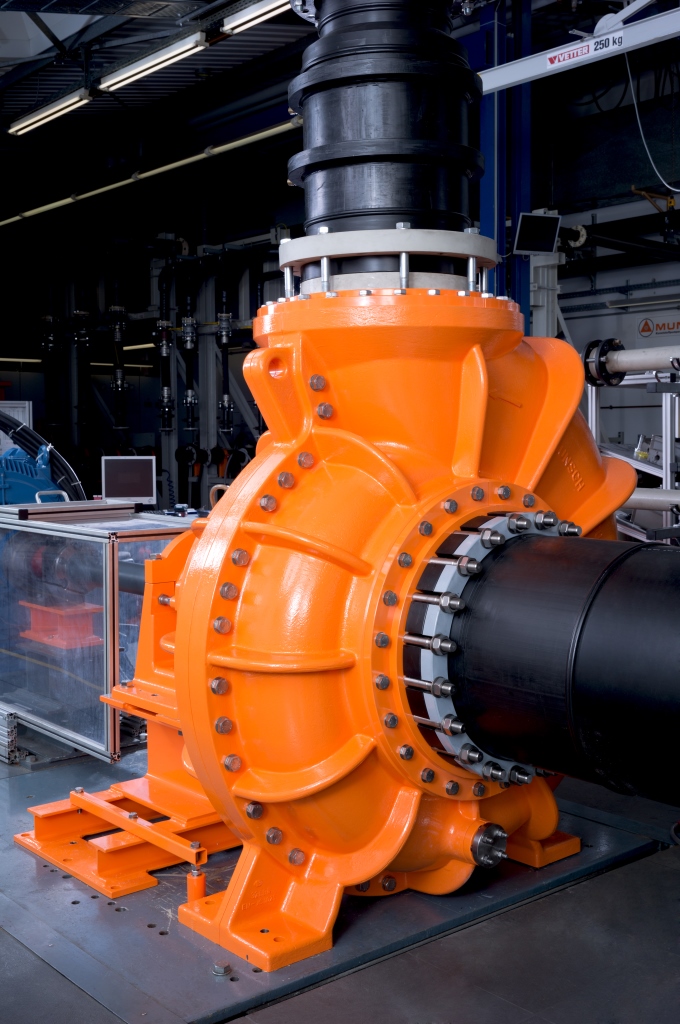

On 15 January 2015, Eveline Lemke, Minister for Economics, Climate Protection, Energy and Spatial Planning presented Munsch Chemie-Pumpen GmbH, Ransbach-Baumbach, with the Innovation Award 2014 of Rhineland Palatinate. This “Crafts“ category award recognizes the development and manufacture of the Mega Mammut non-metallic pump NPC 500-400-700. The Mega Mammut is the world’s largest armoured centrifugal pump for aggressive and abrasive service environments. With a motor rating of one megawatt, it can deliver up to 5,000 cubic metres per hour at a maximum pump head of 40 metres. The heavyweight tips the scales at over three tonnes or even eight tonnes when adding the motor and base plate. Currently, it is being used in a flue gas cleaning system at a copper mine in Africa.

To build a non-metallic pumps of this size, Munsch took a completely new manufacturing approach. This allowed the project to be completed within a record time of only 6 months from the beginning of development through to completion of manufacture. As part of the new manufacturing concept, the pump impeller made of ultramolecular cross-linked polyethylene is fabricated in a single piece despite its size and complex geometry.

The pump lends itself to all applications involving the handling of acids, alkalis, solvents or other chemically contaminated fluids. Typical application examples include the electroplating industry, steel and stainless steel pickling lines, evaporation and regeneration systems including flue gas cleaning systems. The Mega Mammut allows the respective production lines or process systems to be operated with a single pump or a minimum number of pumps, thus reducing technical complexity and increasing plant safety.

Comments