The City of North Las Vegas turned to NETZSCH for a quick turn-around on a custom lube pump solution, resulting in dramatically improved plant performance

The city of North Las Vegas, located in Clark County Nevada, is the fourth largest city in the state. The city operates a state-of-the-art water reclamation facility that serves a population of 224,000 residents and handles a current average flow of 17 million gallons (64.5 million liters) per day. This facility provides the city with extremely clear reclaimable water, maximizing the city’s resource use efficiency through thorough, efficient wastewater treatment.

Recently, the City’s Water Reclamation Facility installed three centrifuges to dry sludge, as well as three progressing cavity pumps from a NETZSCH competitor to pump the dewatered sludge. The dewatered sludge must be pumped from the treatment plant approximately 100 feet (30.5 meters) to a loading dock where it is loaded into trucks for transport. These progressing cavity pumps were designed to operate at 200 psi (14 bar), but during plant operation, the actual system pressure was 290 psi (20 bar). As a result of this high system pressure, maintenance problems began to mount in the dewatered sludge pumping operation, including pressure switch failures and accelerated wear on major pump components. The engineering and maintenance professionals at the facility realized that a solution was necessary to reduce system pressures and therefore prolong pump life.

Customer reaches out for a quick solution

Kenny Eickelberg, the City of North Las Vegas Water Reclamation Facility’s plant engineer, and Layton Brown, the Facility’s chief of maintenance, called James Cooke & Hobson, Inc. in Phoenix for help in solving their high pressure dewatered sludge pumping difficulties.

“With the ongoing operational and maintenance issues in this dewatering application, the customer needed to get a lube pump system designed, built and installed quickly,” said Bruce Loring, a vice president with James Cooke & Hobson who took the call from the North Las Vegas team. “The manufacturer of the original pump system quoted a 15-week delivery schedule for a lube pump system. NETZSCH, who already had a presence with this customer in the form of polymer pumps and thickened sludge pumps operating in the water reclamation plant, said they could design, build and install a custom lube pump solution in six weeks.”

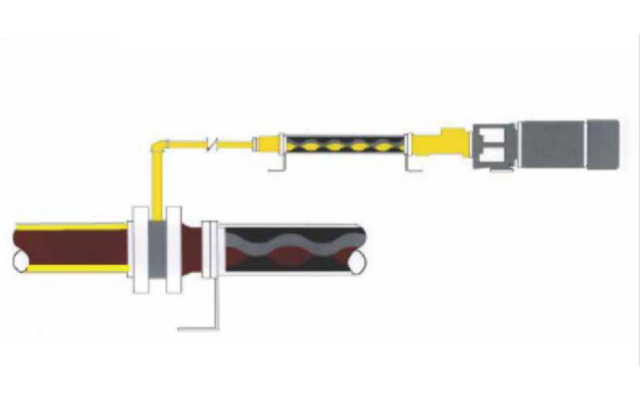

The technical experts at NETZSCH determined that the best solution in this case was to use a Friction Loss Reduction System (FLRS). The FLR System consists of a multi-stage NETZSCH progressing cavity pump and a NETZSCH ring nozzle. The system works by pumping a lubricant – in this case, water rather than polymer to reduce costs – through the pump to the ring nozzle. The ring nozzle is designed to provide a continuous, even layer of water around the entire interior pipe surface so that the dried sludge moves through the pipe at a lower pressure.

While the original design of the dewatered sludge pumping system did not provide for a lubrication system, the NETZSCH FLR system was successfully installed in the first possible flange connection after the competitor’s pump.

System Pressure is Lowered

As designed by the NETZSCH expert engineering team, the lube pump system has a dramatic effect on the dewatered sludge pump line’s pressure.

“By continuously injecting water in the annulus of the pipe, it lowered the pressure tremendously,” Loring said. “The pressure in the system was reduced from almost 300 psi to 150 psi, leading to safer system operation and far less wear on the original dewatered sludge pump system components.”

The NETZSCH FLR system has been operating for approximately two years, and the water treatment facility has seen a longer service life of parts for the dewatered sludge pump. Additionally, the engineering and maintenance team at the facility noted that after installing the NETZSCH lube pump systems, energy demand for pumping the dewatered sludge was significantly lower.

Soon after the first NETZSCH Friction Loss Reduction System was successfully installed, the water treatment facility ordered two more so that all three of the sludge drying lines at the water reclamation plant are now served by a NETZSCH FLR system.

“The bottom line is that without the lube pump solution from NETZSCH, the other pump systems would not have survived,” Loring said.

Comments