Visit Booth # 8614 to see NEMO® BH sanitary advanced pump and NEMO® BO sanitary prime open hopper pump

NETZSCH Pumps North America will be showcasing sanitary pumps ideal for food and poultry applications at the International Production & Processing Expo, which takes place February 12-14, 2019, at the Georgia World Congress Center, Atlanta, Georgia. Stop by # 8614 to see the NEMO® BH sanitary advanced pump for sensitive, abrasive and high viscosity pumps needs. Also on display is the NEMO® BO sanitary prime open hopper pump, ideal for raw material handling, fruits, vegetables, and meat emulsions.

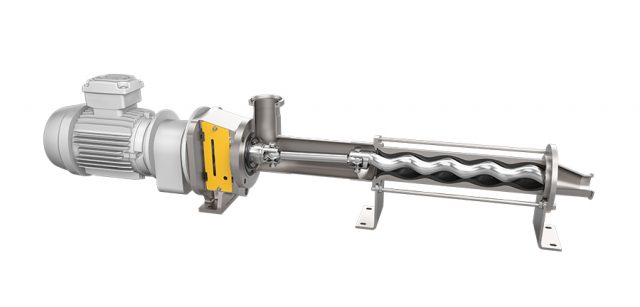

The NEMO BH Sanitary advanced pump on display provides superior quality and versatility for food industries. Appropriate for clean-in-place processes when provided with optional flushing connections, the pump also meets 3A standard requirements and can be disassembled quickly for easy cleaning. The exclusive NEMO progressing cavity modular pump design, combined with food grade Nitrile, EPDM or Viton stators, creates a proven and reliable sanitary pump solution.

The NEMO BH Sanitary advanced pump on display provides superior quality and versatility for food industries. Appropriate for clean-in-place processes when provided with optional flushing connections, the pump also meets 3A standard requirements and can be disassembled quickly for easy cleaning. The exclusive NEMO progressing cavity modular pump design, combined with food grade Nitrile, EPDM or Viton stators, creates a proven and reliable sanitary pump solution.

The pump is ideal for flows up to 200 gallons per minute (gpm)/45 cubic meters per hour (m³/h), pressures of 360 pounds per square inch (psi)/(24 bar), and particle sizes up to 2.5 inches/61 millimeters (mm).

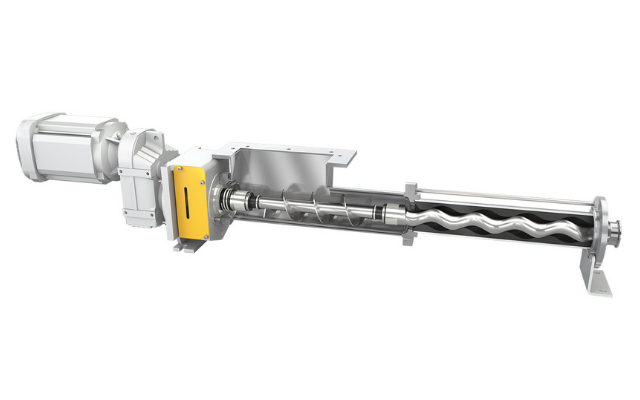

The NEMO BO sanitary prime open hopper pump to be showcased is an FDA-compliant pump for non-free-flowing applications. It is specially designed to handle high-consistency products with a low degree of flowability. These pumps provide continuous, pressure-stable, gentle and low-pulsation conveyance with metering in proportion to rotational speed. The pump handles flows up to 880 gpm (200 m³/h), pressures up to 360 psi (24 bar) and particle sizes up to 3 inches (76 mm).

The pump housing is designed with a larger, rectangular hopper and force-feed chamber. The coupling rod is equipped with a conveyor auger that transports the product into the rotor/stator system. The auger is oversized and provides about 80 percent more flow to ensure improved pump efficiency. The conveyor auger is perfectly synchronized with the rotor/stator system and covers almost the entire hopper opening. The hopper opening can be customized to fit individual specifications.

Comments