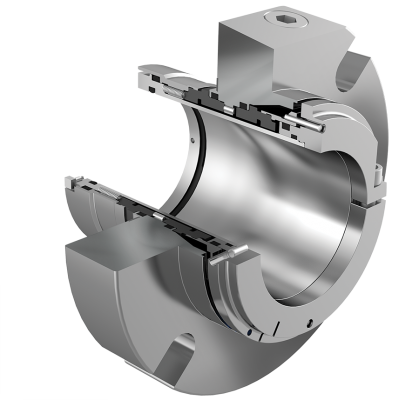

A.W. Chesterton Company is pleased to introduce their latest mechanical seal innovation – the Chesterton 250L Cartridge Double Seal with features that significantly simplify mechanical seal installation. The new 250L uses Chesterton’s proven double seal designs with the additional of a clamp lock ring that allows for single screw tightening. The seal also has internal centering clips which do not require removal.

Designed for ANSI Pumps

The 250L cartridge double seal is designed to fit ANSI pumps used in lower-duty chemical processes such as ethanol grain processing. The 250 double seal provides sealing security that conventional single seals cannot match. A durable back-up seal provides the opportunity for scheduled maintenance to avoid unplanned downtime and production losses.

Meets Pump Sealing Needs for Grain Processing

The need for the 250L came from Chesterton’s customers involved in grain processing who asked for an easy-to-install double seal that would offer barrier or buffer fluid pumping. The maximum sealed pressure was <100 Psig (7 Bar) in their process pumps at lower temperature. Chesterton engineers studied the requirements and realized the low pressure requirements would allow for a clamp lock ring. The clamp lock ring would be easier to install for new maintenance staff and would avoid damage to the equipment shaft or sleeve.

The second key requirement was to eliminate any seal elements such as centering buttons which typically need to be removed and stored to allow for impeller adjustment. These are often removed and stored near the seal on the pump baseplate to allow re-setting of the seal. However inexperienced maintenance staff members may put these loose buttons in their tool boxes or throw them away—causing issues when impeller adjustment is required.

The third requirement was a pumping capability to allow for easy heat removal from the double seal to a buffer or barrier fluid tank. This was made possible with the introduction of tangential pumping geometry — mounting circulation ports tangential to the rotating shaft. The 250L gland barrier fluid ports are designed to enter the seal tangentially to the sleeve. This design enables barrier fluid flow via the “cutwater effect” of the gland geometry.

The innovative design features of the 250L deliver a double cartridge seal intended for, but not limited to, grain processing applications that include abrasive corn kernel slurries, whole stillage, corn syrups, and corn slurry mashes to name a few. The enhanced barrier and fluid flow provide better face cooling and the double seal design offers a back-up seal that helps avoid unscheduled shutdowns due to seal failures (a common concern with single seal failures).

About A.W. Chesterton Company

Operating in over 100 countries around the world, Chesterton is recognized as a leading provider of knowledge backed solutions and expert service for Rotary, Stationary, and Fluid Power equipment supported by a comprehensive line of industrial fluid sealing solutions, high performance protective coatings, and specialty industrial lubrication.

For more information

A.W. Chesterton Company is pleased to introduce their latest mechanical seal innovation – the Chesterton 250L Cartridge Double Seal with features that significantly simplify mechanical seal installation. The new 250L uses Chesterton’s proven double seal designs with the additional of a clamp lock ring that allows for single screw tightening. The seal also has internal centering clips which do not require removal.