The SEPCO Air Seal (SAS) is an engineered pneumatic sealing system designed to seal the shafts of equipment where typical contact seals, such as packing or mechanical seals are ineffective and often too costly to operate and maintain. Designed for wet or dry applications, the seal is particularly successful in powder and bulk solid processes.

HOW IT WORKS

The SAS relies on engineered clearances to develop a uniform sealing pressure/velocity profile using air or gas. This eliminates low-pressure areas and mitigates the chance of product ingress into the seal.

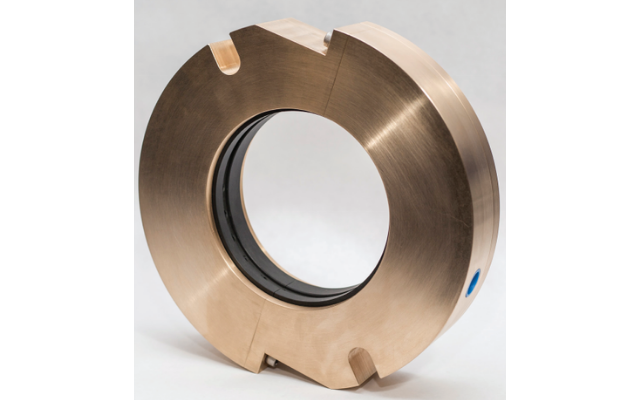

The pressure profile forms a circumferential boundary layer internally that reduces the effects of shaft movement because the throttle is designed to float. The standard SAS is designed so the air fl ow in/ out of the seal is biased at 50% as can be seen in Figure 1. Installed correctly, the SAS is essentially a noncontact seal. For situations in which angular misalignment may exist, the SAS-M is recommended. In all cases, the SAS is engineered to meet our the specific requirements and performance expectations of the end user. Also, see Figure 2 for a detailed drawing of a solid assembled SAS.

WHAT IS THE SAS?

It is a true non-contact air seal. That is ideal for difficult-to-seal applications like powder and bulk solids handling. It can be applied to assets such as:

✔ Mixers

✔ Blenders

✔ Agitators

✔ Pulpers

✔ Screw conveyors

✔ Refiners, and rotor valves

✔ Rotor valves

BENEFITS

The SAS significantly reduces operating costs, and end users save on:

✔ Product waste

✔ Labor and overtime

✔ Seal and other component replacements

✔ Downtime

MAINTENANCE-FREE SEALING

These SAS requires no maintenance as long as air flows continuously to the seal. By design, product does not enter the seal or throttle area. This eliminates the need for maintenance.

The material of construction keeps wear and corrosion from occurring. However, system upsets happen, and if product enters, the seal can be easily disassembled, cleaned, and reassembled.

If the air supply is turned off during operation and with product introduced, the product may enter the seal. This will lead to the internal air passage way becoming clogged, disrupting the uniformity of the pressure profile. Should this happen, seal disassembly may be required. The seal is very simple and can be easily rebuilt, but contact your rep if this occurs.

SAS STANDARD DESIGN PERIMETERS

Maximum working pressure: 60 psi

Maximum misalignment capability

Parallel: 0.0625 inch (total indicator reading)

Angular: 1.5 degrees

Maximum working temperature: 750° F

INDUSTRIES

Pulp & Paper

Food & Beverage

Oil & Gas

Mining

Chemical

Water & Wastewater

Powder & Bulk Solids Handling