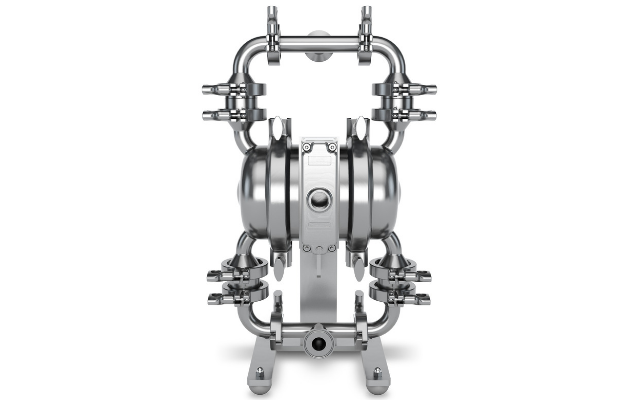

Wilden®, part of PSG®, a Dover company and a worldwide leader in air-operated double-diaphragm (AODD) pump technology, has extended its line of Saniflo™ Hygienic™ Series (HS) AODD Clamped Metal Pumps with the addition of the new PS2 25 mm (1”) model, which comes equipped with the energy-efficient Pro-Flo® SHIFT Air Distribution System (ADS). Saniflo HS pumps offer the versatility, safety and capability needed to efficiently pump an array of viscosities, solids and shear-sensitive products for the food and beverage, pharmaceutical and cosmetics industries.

Incorporating a variety of design enhancements to meet the strictest hygienic and sanitary requirements, Wilden Saniflo HS pumps feature a free-draining flow path that enables clean-in-place (CIP) capability. The Saniflo HS flow-through liquid-path design also eliminates any potential areas where product residue can be trapped and contaminate the product. These design features help ensure the sanitary operation of the pump and, by extension, lowers the risk of cross contamination or compromised finished product that may lead to costly recalls. These features also allow Wilden Saniflo HS pumps to meet or exceed numerous industry standards and requirements, including 3-A, FDA CFR 21.177, USP Class VI, 1935/2004/EC, ATEX and CE.

The Pro-Flo SHIFT ADS further enhances the PS2’s performance and efficiency by providing up to 60% savings in air consumption, more yield per SCFM, precisely metered air consumption for less product waste and maximum Mean Time Between Repair (MTBR). Wilden PS2 pumps offer flow rates to 121 lpm (32 gpm) at a max pressure of 8.6 bar (125 psi). Elastomer options include FDA Buna-N, FDA EPDM, PTFE, Saniflex™ and Wil-Flex™.

For more information about Wilden, please visit wildenpump.com. Wilden is a product brand within PSG, a Dover company. For more information on PSG, please visit psgdover.com.

About Wilden® Pump and Engineering Company:

Jim Wilden revolutionized the pumping industry when he invented the air-operated double-diaphragm (AODD) pump in 1955. Since that time, Wilden Pump and Engineering Company has been at the forefront of bringing AODD technology into the future by building its extensive infrastructure, knowledge base and intellectual capital. Wilden offers a comprehensive line of safe, reliable and energy-efficient AODD pumps – including the Pro-Flo® SHIFT Series, Pro-Flo Series and Specialty Series – for critical pumping applications in the general industrial, paints and coatings, oil and gas, chemical process, water and wastewater, hygienic, mining, ceramics, and military and marine markets. Additionally, Wilden offers the largest selection of AODD diaphragms in the world to ensure your unique application demands are fully met. Headquartered in Grand Terrace, CA, USA, Wilden is part of PSG®, a Dover company. To learn more about Wilden, please visit wildenpump.com.

About Dover Corporation:

Dover is a diversified global manufacturer with annual revenue of approximately $7 billion. We deliver innovative equipment and components, specialty systems, consumable supplies, software and digital solutions, and support services through three operating segments: Engineered Systems, Fluids and Refrigeration & Food Equipment. Dover combines global scale with operational agility to lead the markets we serve. Recognized for our entrepreneurial approach for over 60 years, our team of approximately 24,000 employees takes an ownership mindset, collaborating with customers to redefine what’s possible. Dover is headquartered in Downers Grove, IL, USA.

Comments