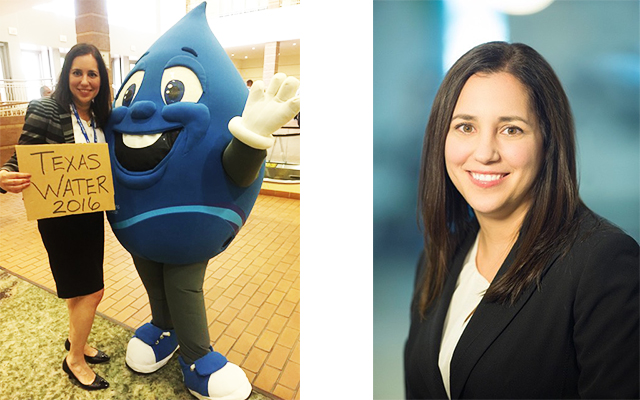

When Empowering Pumps and Equipment was at the Texas Water Conference in April, we had the great fortune of meeting Letty Gomar, Associate Vice President at Carollo Engineers in the Dallas / Fort Worth Area. We invited her to be a Pump Person of the Week and this is what she had to share:

Q. How did you get started working in the Pump Industry?

Letty: My favorite class in college was hydraulics. From there, I started working in the water industry where pumps are commonly used. Over the last 15 years, I have worked in many pump replacement or rehabilitation projects in water and wastewater for municipalities and water districts.

Q.What is your favorite part of your job? What are you most proud of?

Letty: My favorite part of my job is helping clients solve their most challenging problems. I enjoy working with them to find innovative solutions, whether it is optimizing their pumping operations, increasing capacity, or rehabilitating aging equipment and facilities. I’m most proud of the relationships I have built over the years throughout the industry. I continue to learn from incredible people everyday.

Q. What advice would you give to someone new to the industry?

Letty: Not all pumps are created equal. Just because two pumps look the same from the outside, it doesn’t mean they have the same hydraulics or performance. Make sure you evaluate options for your project and talk to people in the industry, including manufacturers, operators, engineers, contractors, and managers. Each person will have a different perspective to consider for your project, and people in the industry are willing to help.

Join our LinkedIn Group:

Join our LinkedIn Group:

Empowering Women in Industry!

Q. What are the top 5 questions you get asked by your customers? How do you answer them?

Letty: There are a few questions I always get asked: 1) Will this work? There’s always some level of doubt in the solution we find to the problem. It can be related to a new technology being implemented or a unique situation in the field. Before I answer this question, I make sure that I consult with other experts in the industry and am confident that the solution will work. I will also present the advantages and disadvantages so that the owner can make an informed decision.

2) How much will it cost? Cost estimating for a project is an art. There are published costs

for equipment, but there are so many uncertainties in each project that translate into risk.

Risk then can influence the prices and costs for the project to be built. As I develop the

cost estimates, I include factors that will account for risk. The question comes from the

owner to be able to budget the capital expenditures appropriately, so it typically is one of

the first questions asked.

3) Is it constructible? Some people think engineers only draw lines on paper. While on the

surface it can look like that, there is a lot of education, experience and judgement that

comes when designing a project. This experience includes involvement during

construction for the projects that we design. It becomes a critical component when

developing the design. Just because a pump can hydraulically do the work, it doesn’t

mean it can fit in the existing structure.

4) Have you done this before? Throughout my experience, I have found every project is unique. While you can find similarities between them, each one has it’s own challenges.

Experience is learning from each unique situation and finding ways to apply the lessons

learned to new situations.

5) How will this project impact my operations and maintenance? Owners and operators

want to know if the project or new equipment will add costs or require new staff. If it is a

new technology, there might need to be training provided to the operators. If there is

added capacity, it might mean that there are higher energy costs. These impacts to O&M

can drive the project direction and determine its success.

On behalf of the entire team at Empowering Pumps & Equipment, Thank you for being our Pump Person of the Week! We look forward to keeping up with you as you continue advancing in your career in the Pump Industry! We know you will do great things!!

Know an Amazing Person who is making valuable contributions within the Pump Industry? Nominate them to be “Pump Person of the Week”!

Know an Amazing Person who is making valuable contributions within the Pump Industry? Nominate them to be “Pump Person of the Week”!

Comments