Early in 2021, a valve manufacturer needed quality seats (glass-filled PTFE), gland packing (PTFE), and bottom packing (PTFE) for its new valves. They needed quick delivery, which was a struggle for their current component producer.

The team reached out to SEPCO and its P3 division to request these valve parts. The Texas-based P3 team solved the manufacturer’s challenge with its Thermex machined parts, which are also available for repair shops, end users, and any personnel on the plant floor. Cody Kaufmann, the P3 Plastics business unit manager, explained what the manufacturer needed and how P3 helped out in this Q&A.

The team reached out to SEPCO and its P3 division to request these valve parts. The Texas-based P3 team solved the manufacturer’s challenge with its Thermex machined parts, which are also available for repair shops, end users, and any personnel on the plant floor. Cody Kaufmann, the P3 Plastics business unit manager, explained what the manufacturer needed and how P3 helped out in this Q&A.

What valve types does the manufacturer produce?

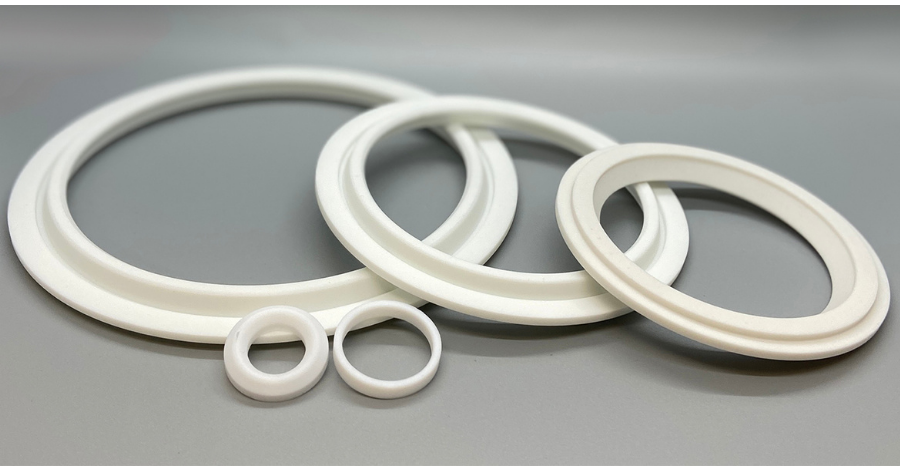

The manufacturer makes a number of different valves, but we supplied the seals for their high-performance butterfly valves and ball valves. They are double-eccentric (double-offset) designed valves. According to their website, this design decreases torque and increases service life by minimizing the seat-to-disc interference throughout the disc travel.

What was the manufacturer’s main problem with the components they previously used?

They came to us was they were having supply issues with their current vendor. Having quality parts in a timely manner is vital for them.

How did P3 help solve the problems?

Having the ability to compound the PTFE materials on location coupled with our in-house molding and machining meant that we were immediately began producing their parts without the need to wait on other supplies. This allowed for a quick and seamless transition that eliminated downtime for the manufacturer.

Is the manufacturer satisfied with the components and their reliability?

Yes. We called to check in recently, and they said this issue has turned into a blessing for them, which makes me really proud of our team. This is exactly the kind of feedback we love to hear.

What did your team do to make sure the product was delivered on time?

We put a priority on making sure that they got the parts in their hands as soon as possible. At the same time, we emphasized quality, as we do with all our plastics. The last thing we wanted was for them to lose time during the transition because the parts didn’t meet their expectations. As I mentioned, this was only possible because our production’s vertical integration puts full control of quality and delivery in our hands.

What else should potential component users know?

When customers call, they don’t reach voicemail or a recording. They talk to a person who listens to their needs, develops solutions, and turns what they think is a problem into a blessing. We have a small company feel with the knowhow and capacity to solve big company problems.

Comments