Turbomachinery R&D company shifts turbomachinery engineering AI program into high gear for NASA SBIR project with far-reaching impacts.

Start spooling your jet engines and your computer fans, because SoftInWay is embarking on a new R&D project thanks to its latest SBIR award from NASA. SoftInWay will seek to improve the methodologies and workflows that are currently used to develop highly complex turbomachinery.

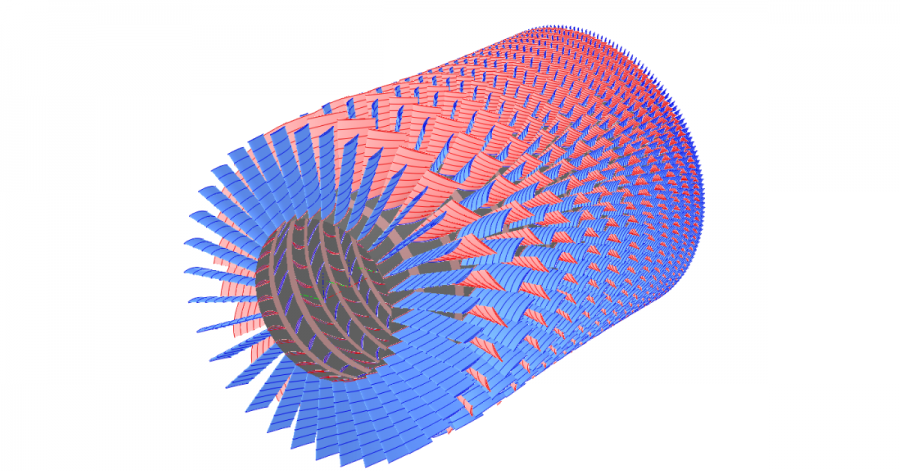

Compressor efficiency is one of the most important factors in developing an efficient gas turbine engine. Often, it can take years of designing, building, and testing a compressor before a proper design is found which operates both reliably and efficiently. With the AI and machine learning technology being developed by the SoftInWay team, optimizing a compressor, or any turbomachine for that matter, to function at optimal performance will be possible in weeks instead of years.

Naturally, creating an autonomous program that can accurately optimize a compressor’s operating efficiency and generate performance maps is a daunting task. At the heart of the program, however, will be the AxSTREAM platform, more specifically, the AI capabilities being created in AxSTREAM ION. This new AI-based workflow will be trained using AxSTREAM, but it can also be trained using proprietary software and third-party codes such as those at NASA. These programs will be able to automate performance data generation for compressors in this test case. When subsequently combined with data gathered from test rigs, the autonomous AI program will be able to generate accurate turbomachinery performance data, with minimal error percentages; significantly shortening the time required to design a complex machine such as a multistage compressor.

The potential impact on the industry that this project offers cannot be understated. Every manufacturer from industry stalwarts such as General Electric and Siemens to startup companies are all looking for ways to cut development time and costs on advanced turbomachinery projects. This technology will go beyond axial compressor R&D, into applications such as turbopump design for liquid rocket engines, as well as turbocharger design. While all of these machines are very different, the engineers creating them all share a common challenge, which is being able to create more powerful, efficient, designs which operate optimally in ever-shortening time frames.

Dr. Maksym Burlaka, the Project Leader, said that while the project is daunting, SoftInWay’s engineering team is more than up to the task. “We’re not ones to back down from a challenge. The big objective for us will be to streamline this workflow with our AxSTREAM platform and the other tools at our disposal and allowing them all to work in tandem.

AxSTREAM will of course be critical in this project, as it is the foundation upon which this infrastructure will be built, and it’ll be relied upon to optimize the compressor’s performance and operating conditions in this test case as well as countless other turbomachinery in future projects. Obviously we will be handling the design work as well, however the operation performance and optimization will be sanity checked by AxSTREAM, and in turn we will be sanity-checking the iterations given to us by AxSTREAM.” Dr. Burlaka added that they aim to prove that while complex turbomachinery designs are the future of mechanical engineering, a long development period is something that can be left in the past.

SoftInWay’s engineering team is confident that the framework being developed here for predicting and optimizing compressor operation will set a precedent in turbomachinery R&D going forward. With the successful completion of this project, the era of spending years developing one turbomachine will end.

About SoftInWay, Inc.

SoftInWay, Inc. is a global R&D engineering company specializing in the development of efficient turbomachinery components and systems by offering its integrated and automated software platform, AxSTREAM ® for all steps of the turbomachinery design, redesign, analysis, and optimization process (including complete 3D design, thermodynamic cycles, rotor dynamics, and secondary flow and cooling system simulation). SoftInWay also offers a number of engineering services and educational courses, available both online and in a classroom-style setting.

SoftInWay is ISO 9001:2015 and AS9100:2016 certified and committed to providing our customers with products and services that meet international quality standards.

SoftInWay supports more than 450 companies worldwide, and works closely with universities, research laboratories, and government organizations. You can find more information at www.softinway.com

Comments