Contributor: Dorota Zoldosova, Head of Marketing and Communications, Sulzer Chemtech Ltd.

Sulzer’s advanced VIECTM boosts oil-water separation

By delivering top performance in liquid-liquid three-phase separation, Sulzer’s electrostatic coalescer internals for vessels VIECTM is the ideal processing technology for oil and gas upstream operations. The solution can maximize productivity and separation efficiency, even in the most challenging oilfields.

While global oil demand remains solid, a growing number of oilfields are reaching maturity, i.e. they are characterized by higher volumes of free and emulsified water in oil emulsions. As a result, the effective removal of undesirable water from crude oil is increasingly important for onshore and offshore processing facilities. To help the upstream sector address these challenges, Sulzer Chemtech, the leader in separation and mixing technology, has developed a solution that enhances separation performance.

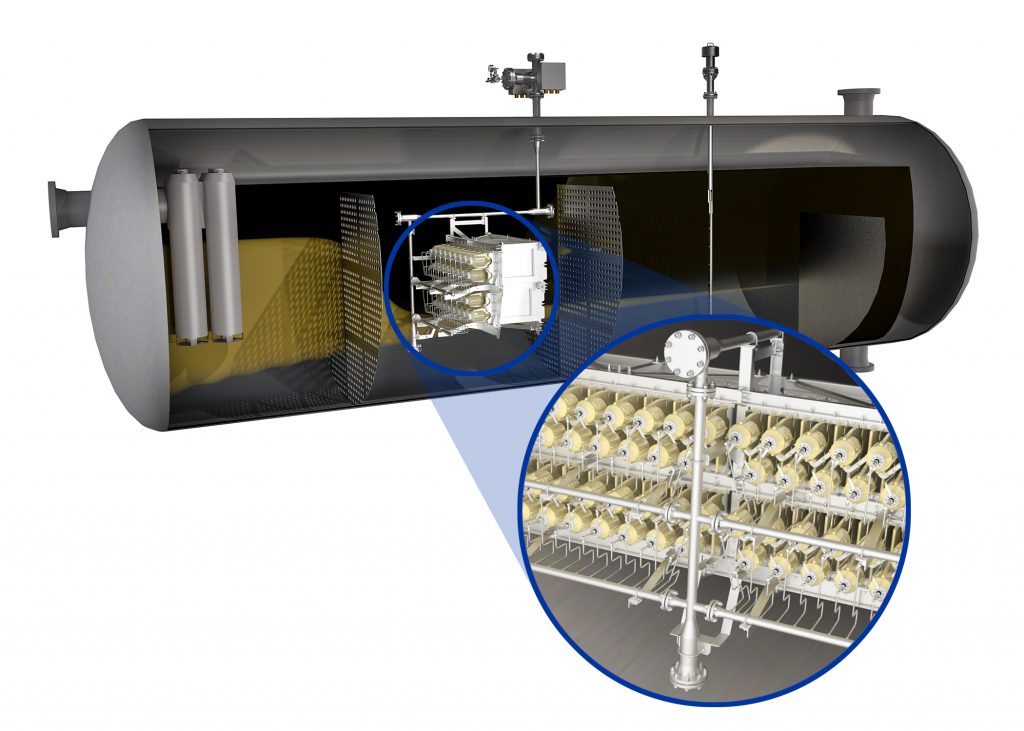

Sulzer’s VIEC is an electrostatic coalescer equipped with fully insulated electrodes. It can be installed in new separators or retrofitted in existing vessels and forms a cross-sectional wall that forces emulsions through a high-voltage electrical field. As a result, while gas leaves the separator from the top, the water droplets merge together and fall to the bottom of the separator. At the same time, oil flows through the vessel for subsequent processing.

By fully insulating the VIEC’s electrodes, Sulzer has built great flexibility and robustness into its solution, allowing the VIEC to withstand any concentration of water and gas. This is the case even when the feed contains very high volumes of water. Therefore, it can be installed in the early separation stages to remove most of the water in the emulsion, as opposed to conventional electrostatic coalescers, which do not tolerate high amounts of water and gas.

VIEC™ – Vessel internal electrostatic coalescer is a technology for enhancing liquid-liquid separation by using alternating high voltage electrical fields.

Sulzer’s solution can deliver crude oil with purities comparable or higher than systems featuring gravity separators, coalescers and dehydrators. Consequently, upstream facilities can greatly streamline their processes, reducing the size of conventional oil separation trains and the number of stages. This leads to lower capital expenditures (CAPEX) and noticeable improvements in overall separation efficiency.

Energy, time and resource efficiency are also optimized. The VIEC allows the separation process to run at lower temperatures, characterized by higher viscosity fluids, and reduces the volumes of demulsifying chemicals needed. Water droplet aggregation is promoted by the electrical field, thus leading to faster growth rates and settling times. Upstream oil and gas companies can therefore benefit from substantial savings in operating expenses (OPEX).

For those looking to introduce this new technology to their existing systems, VIEC can increase separator’s capacity by enhancing the oil-water separation process. When chosen for new installations, it allows businesses to opt for smaller separators whilst ensuring high throughput, optimizing facility footprint.

The high performance of Sulzer’s VIEC makes it ideal for even the most challenging applications in the upstream sector. For more information on VIEC and how it can support your business visit www.sulzer.com/vessel-internal-electrostatic-coalescer.

About Sulzer

Sulzer, headquartered in Winterthur, Switzerland, is a global industry leader in pumping solutions and services for rotating equipment, as well as separation, mixing and application technology.

Sulzer Chemtech provides processing industries with mission critical technologies and equipment, whether they are in the oil & gas, chemical, pharmaceutical or food and beverage sectors.

Our capabilities extend from technology licensing through products to services, offering customers a one-stop concept for the design, manufacture, maintenance, repair and upgrade of process equipment.

The range covers individual components, such as column internals, complete units, skids and technologies for refineries, petrochemical and bio-polymer plants.

With over 180 production and service sites around the world, we deliver solutions that truly support our customers.

In 2018, we achieved sales of CHF 3.4 billion with around 15’500 employees. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

Comments