Sulzer supports BEWiSynbra Group’s circular EPS strategy

Author: Dorota Zoldosova, Head of Marketing and Communications, Sulzer Chemtech Ltd.

Sulzer Chemtech has completed the design, installation and start-up of an advanced production line for expandable polystyrene (EPS) for the BEWiSynbra Group. The company is one of Europe’s leading producers of EPS and the new unit will support its ambitious target to collect and recycle 60,000 tonnes of EPS annually by utilizing recycled materials as feedstock.

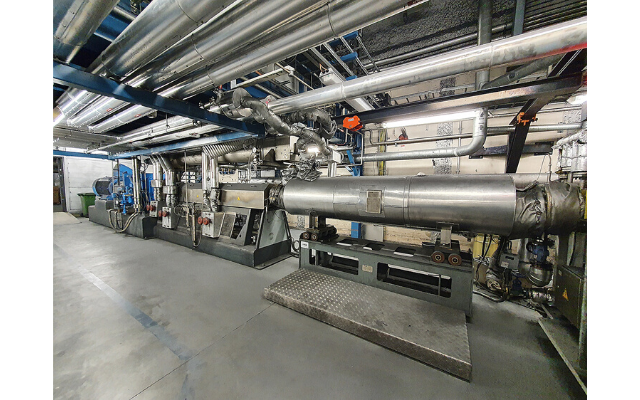

Sulzer, the leader in separation and mixing technology, has delivered a state-of-the-art EPS production line to the BEWiSynbra Group’s facility in Porvoo, Finland. The new unit utilizes Sulzer’s patented extrusion-based melt impregnation technology and has the capacity to produce over 10,000 tonnes of EPS per year from both recycled as well as virgin materials.

The production line has the capacity to produce over 10,000 tonnes of EPS for building installation and packaging per year from both recycled as well as virgin materials.

The new asset will help the BEWISynbra Group expand its plastic manufacturing capacity while also enabling it to meet its circular economy targets. The production line can convert EPS post-consumer waste into new EPS material used in applications such as building insulation or packaging.

Jonas Siljeskär, CEO of the BEWiSynbra Group, comments: “The new EPS extruder line designed and delivered by Sulzer allows BEWISynbra to broaden its EPS portfolio. It enables us to grow our volume of recycled materials, while improving our production efficiency as well as reducing our costs for repair and maintenance”.

Philipp Süess, Head of Sulzer Chemtech ERA, concludes: “It is exciting to see our solutions play a key role in increasing the competitiveness of our customers as well as supporting their ambitious sustainability practices. We look forward to working with BEWiSynbra Group in the future.”

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2019, our 16’500 employees delivered revenues of CHF 3.7 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

The Chemtech division is the global market leader in innovative mass transfer, static mixing and polymer solutions for petrochemicals, refining, LNG, biopolymers and biofuels. Our product offering ranges from process components to complete separation process plants, including licensing. Customer support covers engineering services and field services to tray and packing installation, tower maintenance, welding and plant turnaround projects.

Comments