Nordlaks is a Norwegian fully integrated company that produces, processes and sells Atlantic salmon and rainbow trout worldwide. It has recently completed the building of a new smolt facility for fish up to 500 grams at Innhavet in Hamarøy municipality. This RAS (Recirculating Aquaculture System) fish farm is the biggest of its kind in Norway, with a special focus on smolt welfare. The land-based facility has state-of-the-art equipment for optimal biosecurity and sustainability. At the heart of the RAS process, all recirculation pumps were supplied by Sulzer.

The challenge

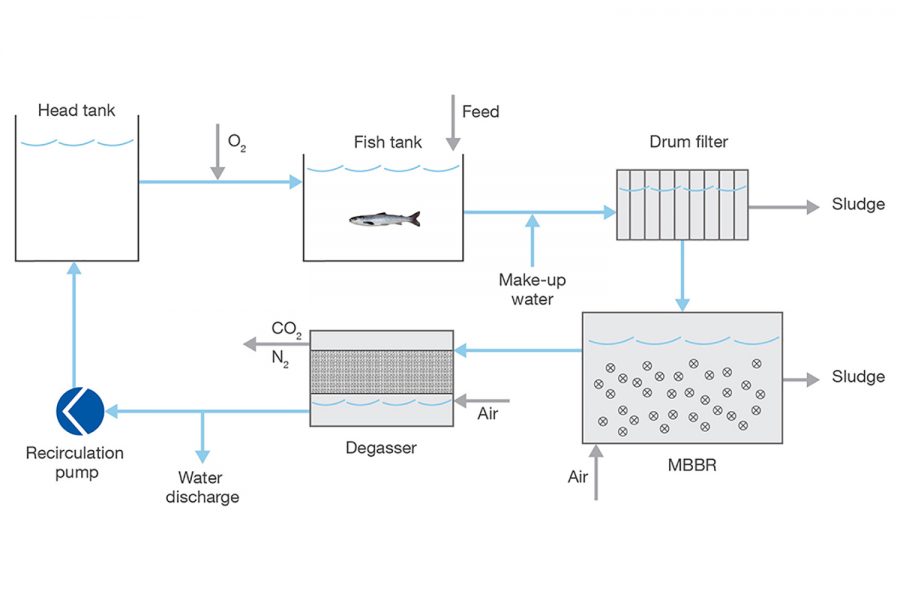

The Innhavet RAS plant has 34 fish tanks of different capacities (350 to 1’000 m3) in 5 separate main sections. Each section is independent from the others and includes its own complete water treatment system in a semi-closed loop (98% recirculation + 2% make-up water). The brackish water from the fish tanks first flows by gravity to a rotating drum filter for the removal of the main suspended solid particles. It then falls into an MBBR (Moving Bed Biofilm Reactor) for TAN (Total Ammonium Nitrogen) reduction. After passing through a countercurrent degasser for the stripping of nitrogen and carbon dioxide, the treated water is finally pumped to some head tanks, prior to oxygenation and return to the fish tanks.

Five AHLSTAR A43-500 recirculation pumping units for brackish water

In each fish tank, the water is fully renewed every half an hour. The well-being of the smolts is highly dependent on a constant flow of water through the facility. The reliability of the recirculation pumps is, therefore, of paramount importance.

High overall energy performance of the RAS plant means a better environmental footprint and reduced operating costs. Consequently, the main components of the water treatment loops must have top-class efficiencies, particularly the recirculation pumps.

The solution

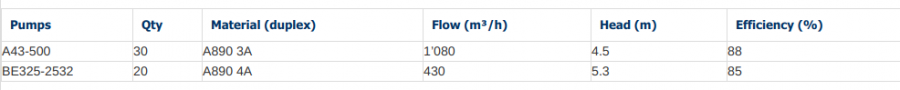

As a long-term supplier of equipment (pumps and turbines) to other Nordlaks plants, Sulzer was involved at an early stage of the new project. In collaboration with the Momek Group, a large industrial service provider in Scandinavia, the pumps were carefully selected, not only to fulfil the requirements during the warranty period, but to run optimally and economically during the whole lifetime of the site. For the recirculation of the brackish water, 50 AHLSTAR and BE process pumps in duplex material have now been installed and are operating continuously. In addition, 5 VUPX submersible propeller pumps are used on intermittent duty when the fish tanks are emptied during the transfer of smolts.

Five BE325-2532 recirculation pumping units for brackish water

Customer benefit

By choosing to work with a trusted partner, the client made sure to get fast and permanent technical support, in addition to the best products. The recirculation pumps have the following major advantages:

Extremely high hydraulic efficiencies that by far exceed the strictest energy regulations for water pumps. This means huge energy savings over time and smaller total cost of ownership.

Duty points close to BEP (Best Efficiency Points), low rotation speeds and rigid baseplates grouted in concrete. The pump units are working smoothly with minimized vibration levels.

Superior-grade material for all wetted parts. For the choice of pump material in contact with brackish water, the long-term perspective favored duplex stainless steel rather than 316SS. Duplex steels have better design strength than austenitic stainless steels, as well as higher corrosion, abrasion and pitting resistance. In the end, maintenance costs and the risk of downtime are reduced.

Sulzer is a recognized supplier in the fish farm market, with innovative and proven pumping, mixing and aeration solutions, and provides highly energy-efficient products with low life-cycle costs and the smallest possible environmental footprint. As a material specialist in a wide range of fresh water, brackish water, seawater and brine applications, we can offer pumps in cast iron, 316 stainless steel, duplex, super duplex, SMO, etc.

Project data

50 AHLSTAR and BE recirculation pumps (continuous duty) in water treatment loops. The dry-installed single-stage overhung pumps are equipped with semi-open impellers and single mechanical seals.

Five VUPX-0402 (2’280 m³/h @ 3 m) submersible propeller pumps (intermittent duty) for the emptying of fish tanks.

Water treatment system process chart

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2019, our 16’500 employees delivered revenues of CHF 3.7 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Pumps Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Comments