Theory bites are a collection of basic hydraulic theory and will touch upon pump design and other areas of pump industry knowledge.

Cavitation is the Phase change from liquid to vapor brought about by reducing the local pressure anywhere in a pump below the vapor pressure.

Simply defined, cavitation is the formation of bubbles or cavities in a liquid, developed in areas of relatively low pressure. The imploding or collapsing of these bubbles trigger intense shock waves inside the pump, causing significant damage to the impeller and/or the pump housing.

Cavitation is a significant concern in several application areas, including pumps, inducers, marine propellers, water turbines, and fuel injectors. One of the major problems caused by cavitation is a loss of pressure rise across a pump. Other problems include noise, vibration, and damage to metal components.

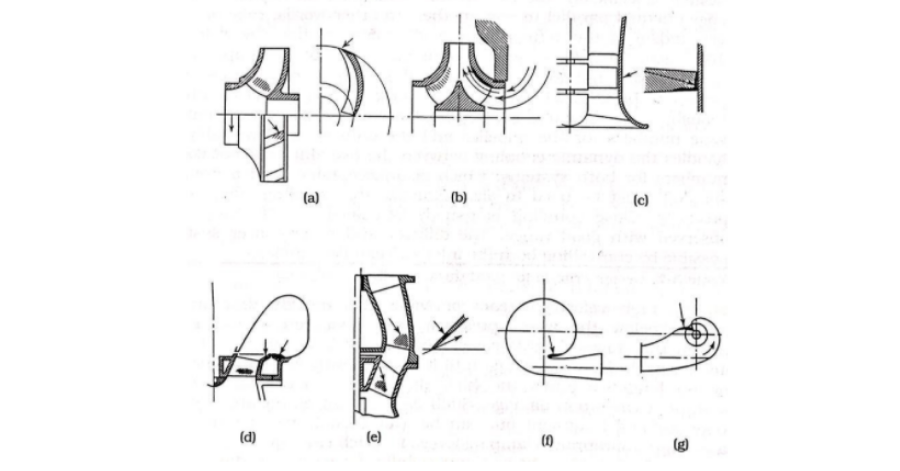

The simplest model of cavitation onset requires the local static pressure to drop below the vapor pressure in the fluid being pumped. Although this would be expected to happen principally at the inlet of the first stage, for example in a multistage pump, and while this is generally true, it also can occur at numerous other locations.

Check Stepanoff 1597, Centrifugal and Axial Flow Pumps for more details.

Source: Centrifugal Pump Design and Performance, 1997 D. Japikse

Read more Theory Bites!

Comments