Theory bites are a collection of basic hydraulic theory and will touch upon pump design and other areas of pump industry knowledge.

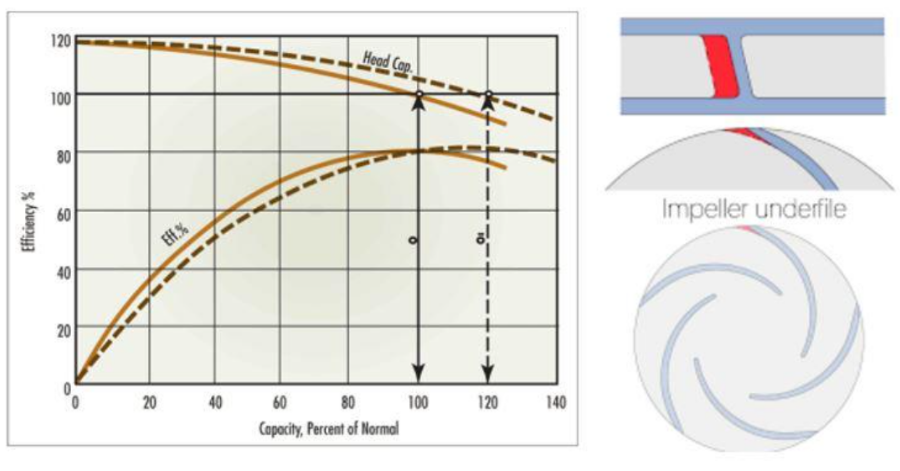

Blade underfiling refers to the material removal at the Impeller Blade Trailing Edge; it is the removal of material from the underside (also backside, “non-working” side, or suction side) of an impeller vane at the inlet or the exit.

Impeller underfiling is primarily a means of establishing dimensional uniformity at the vane exit tips. Vane-to-vane uniformity, in turn, reduces variation in performance from one pump to the next.

Underfiling also “straightens” the vane outer diameter surface or “land”. Some manufacturers do not under file, except when needed after a performance test.

Underfiling is also used to increase the pump head versus flow (H-Q) performance. This can be thought of as either increasing head or increasing flow. The potential for the increasing head can be in the range of a few percent to as much as 10%.

Underfiling or overfiling may also bump up the pump efficiency a bit – usually not more than 0.5%.

Source: Randal Ferman Consulting Engineer, Vice President of Ekwestrel Corp. and WaterWorld

Read more Theory Bites!

Comments