Theory bites are a collection of basic hydraulic theory and will touch upon pump design and other areas of pump industry knowledge.

The impeller tip speed plays a vital role in the centrifugal pump handling liquid containing solid particles. Engineers have to take extreme care to check the impeller tip speed during the engineering phase. The improper selection may lead to the continuous problem and premature failure of the pump during normal running conditions.

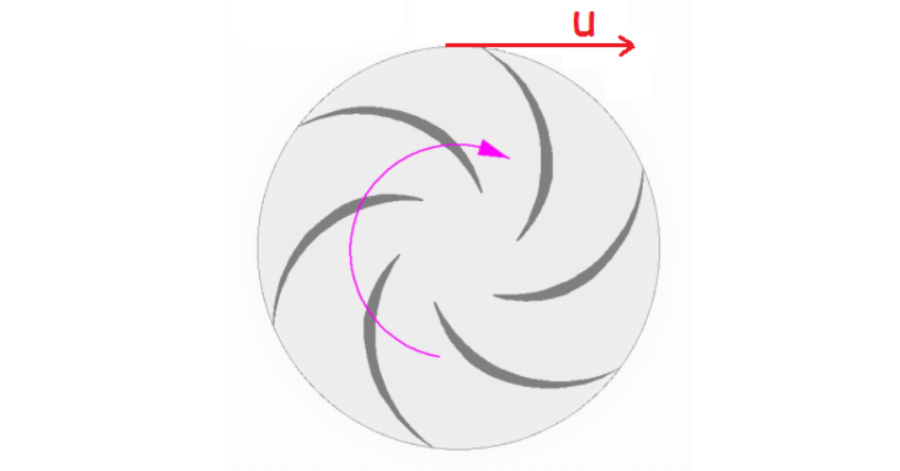

Impeller Tip speed is used to define the velocity produce at the impeller tip. It is due to the rotation and diameter of the impeller. Impeller tip speed is an essential parameter when the pumping liquid contains solid particles. When the tip speed increases the rate of erosion will be high and it will lead to premature failure of the pump: For dirty water-type applications, limited to 40 m/s. (130 feet/s)

Source: Mechanical Engineering

Read more Theory Bites!

Comments