Theory bites are a collection of basic hydraulic theory and will touch upon pump design and other areas of pump industry knowledge.

Impeller trimming refers to the reduction of the impeller diameter, and thus a reduction of the circumferential speed at the impeller outlet of a centrifugal pump.

Impeller trimming is a proper way to alter the performance of a centrifugal pump with a constant speed so as to meet the demand on the specified flow rate and head in pumping systems.

The affinity laws accounting for the impeller trimming is the key relation to determine the pump performance with a trimmed impeller anyway they are not as accurate as we would like them to be, especially if we are making more than a 10% reduction in impeller diameter.

- The affinity laws assume the impeller shrouds are parallel. This is true only in low specific speed pumps.

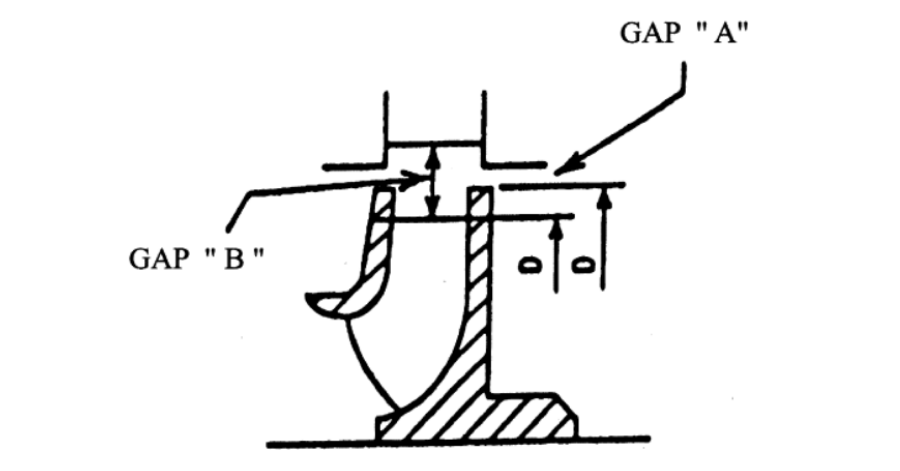

- There is increased turbulence at the vane tips as the impeller is trimmed because the shroud to casing clearance (Gap “A”) is increasing. This is sometimes referred to as “slip”.

- The liquid exit angle is changed as the impeller is cut back, so the head/capacity curve becomes steeper

Read more Theory Bites!

Comments