Theory bites are a collection of basic hydraulic theory and will touch upon pump design and other areas of pump industry knowledge.

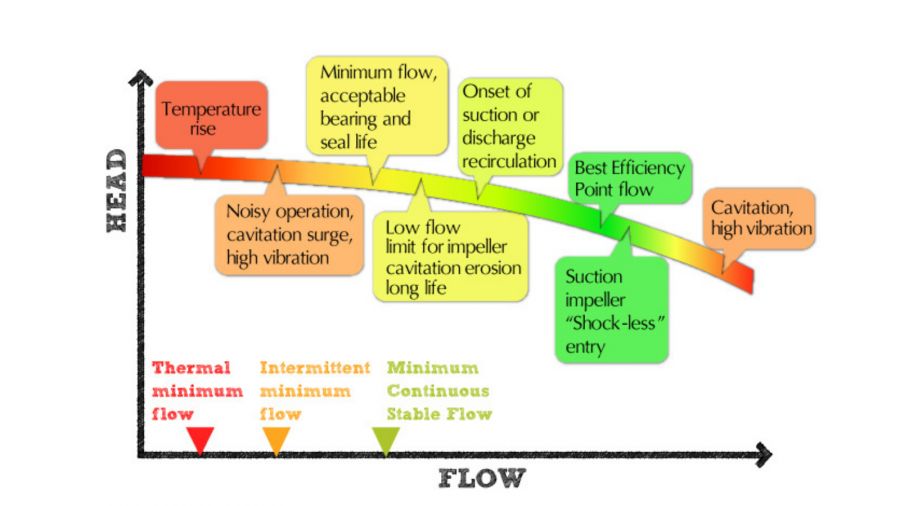

MCSF is an acronym that stands for Minimum Continuous Stable Flow. It is the minimum flow that must be maintained through a pump to avoid excessive recirculation at the impeller inlet.

When a pump is operating at BEP flow through the impeller is very stable and uniform. However, as the flow produced by the pump decreases and the operation of the pump moves to the left of BEP, some of the liquid begins to move in a circular pattern: it enters the impeller inlet but then comes back out of the inlet and then is drawn back in again.

This circular and irregular flow pattern is known as recirculation. The more flow is reduced, the greater the amount of recirculation within the impeller inlet. Once recirculation becomes excessive it will result in increased vibration and pressure pulsations.

Pump manufacturers make a determination, based on Engineering analysis and experience, and establish the minimum flow that must be established to avoid excessive recirculation. This minimum flow point is called the minimum continuous stable flow or MCSF.

For more details check out Randal Ferman article:

http://ekwestrel.com/what-is-the-purpose-of-minimum-flow/

Read more Theory Bites!

Comments