Over the years, the team at TPCI has noticed a recurring issue: Many companies with pumping applications will not replace their pump components when necessary. Instead of following the recommended maintenance cycles, they often wait until there’s an emergency or something breaks or fails.

To make matters worse, many times these companies do not have replacement pump parts readily available in the shop. Not only does this put major stress on maintenance personnel trying to solve the problem, it also necessitates production halts, which waste time and money. Pumping systems can account for anywhere from 25 to 50% of an industrial plant’s energy usage, so the added downtime and expenditures can be significant.

When accessing pump parts for maintenance, “time is money.” Regardless of the reason for the pump part shortage — whether dealing with an obsolete component or a part made from rare materials — any delays in rehabilitating the pump will result in lost revenue.

Understanding the various components of the total cost of ownership can help manufacturers reduce the energy, operational, and maintenance costs associated with pump part maintenance. Performing this life-cycle cost analysis (LCCA) allows for reduced energy use and waste while maximizing operational efficiency.

Typically, pumping systems have a lifespan of about 15 to 20 years. To calculate your system’s LCCA and ensure it reaches its maximum working life, you’ll need to know the recommended maintenance cycles for your specific pumps and pump parts, which the original manufacturers can advise upon in terms of frequency and extent.

Supply and demand govern manufacturing capacity. If certain pump parts become difficult to access, the user’s options are limited, and they will be forced to:

- Seek out an independent distributor specializing in procuring hard-to-find parts

- Incur a higher cost of components

- Lose time vetting product quality

- Annihilate productivity

To avoid this scenario, it’s critical to be proactive about routine maintenance and replacement parts. To do so, however, manufacturers first must understand what causes the system harm. One of the leading causes of pump breakdowns, for example, cavitation. Vibration, pounding from cavitation is often transmitted from the fluid end through plunger and extension rods to the crankshaft & bearings in the power end, shortening pump life.

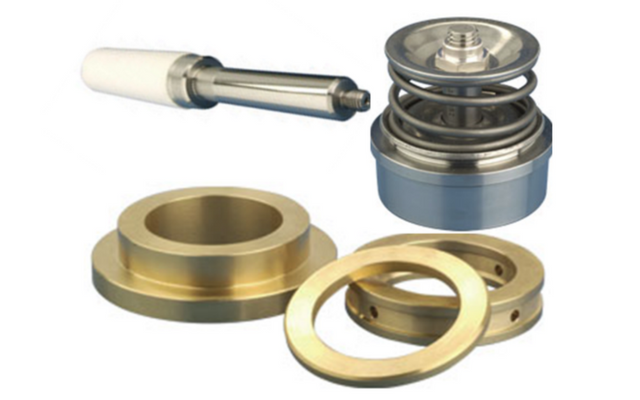

TPCI’s pump parts support applications across industries, from oil and gas to food processing. While stocking up on spare parts is paramount to proactive maintenance (especially if they are subject to raw material availability or could become obsolete), our experienced team can provide recommendations for anyone finding themselves in an emergency situation.

Wondering how often you should replace your pump components? Our in-house experts are available to address any pump maintenance and part selection questions you may have. Contact Triangle Pump Components today!

Comments