Author: Bill Lenling, TST Coatings

The use of thermal spray coatings can greatly improve the performance of several different pump components. Pump parts such as plungers, mechanical face seals, rotors, and housings are examples of components that operate at higher levels of operation with the addition of a properly engineered coating. The engineering of the proper coating is highly specific to the part being coated, it’s geometry, the material in which the component is made, the operating conditions of the pump, and materials being pumped. With a good understanding of these variables, along with expertise in coating processes and coating materials properties the proper coating can be engineered to meet and sometimes exceed the expectations for the coated component.

Operating Conditions

Thoroughly understanding a pump’s operating conditions is critical in the engineering of a performance enhancing coating. Understanding the pump media being pumped needs to be considered first. Are there abrasive particles, if so what is the size, morphology, hardness, and concentration of the abrasive? Materials that may not seem to be obvious abrasives such as toothpaste or paint pigments can create very high pump wear when pumped in high concentrations. Is there a corrosive element of the media being pumped? When a corrosive component is present, is the media acidic or caustic, and what is the concentration. Understanding the corrosive element will narrow the selection of materials that can be considered in the coating design. In many cases, the media being pumped contains both abrasives and corrosive elements, in which both need to be considered during the coating’s material selection.

The operating temperatures of the pump can be a significant factor in the coating design. An example is if the pump component to be coated is made from a higher thermal expansion material such as austenitic stainless steel, the expansion and contraction of the base metal can affect the adhesion of a lower expansion material in the coating. Carbides and ceramics, such as tungsten carbide and oxide ceramics, can provide excellent wear and corrosion resistance, but typically have lower thermal expansion coefficient. Medicating the mismatch in thermal expansion of the base metal and coating thus needs to be considered.

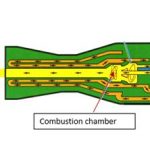

The pressure in which the pump operates will also be a factor to consider in the coating design. When pumping at very high pressures, the adhesion mechanism of the coating can be a critical design criterion. In oil and gas hydraulic well stimulation pumps, pumping pressures can be as high as 15,000 psi with pumping liquids and abrasives. Pump plungers are coated to improve the plungers wear resistance. Because of the high pressures, the coating needs to be metallurgically bonded to the plunger to avoid delamination that could occur if the coating was only mechanically bonded.

RELATED ARTICLE: Thermal Spray Coatings for Metal-Seated Valves

RELATED ARTICLE: Thermal Spray Coatings for Metal-Seated Valves

Pump Component Geometries

The shape of the component that is to be coated needs to be considered for the application of a coating. Many coating processes, like thermal spray, are line of sight, so surfaces in where the line of sight angle is less than 45 degrees cannot be coated in most cases. For example, inside diameters of cylindrical parts cannot be coated, but outside diameters can be. Coating of sharp corners should be avoided due to them causing stresses that build up in the coating as the coating is applied. The stress in the coating can weaken the bond strength of the coating and even cause delamination. When designing a component, sharp corners should be changed to radiused or chamfered designs.

Coating thickness is an important variable to consider. Almost all coating processes have thickness limitations. In the case of vapor deposited coatings, both PVD, (physical vapor deposition) and CVD, (chemical vapor deposition), coating thicknesses are typically limited to a few micrometers, compared to thermal spray coatings which a thin coating starts around 50 micrometers and can be hundreds of micrometers in thickness. Understanding how thick the coating needs to be in order to be effective in improving the components performance will narrow the selection of which coating technologies can be considered.

Coating Materials Selection

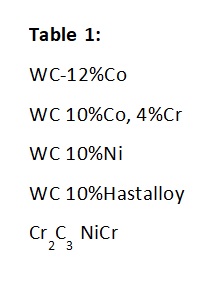

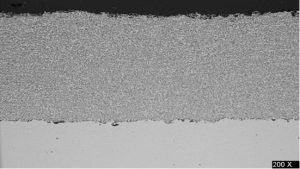

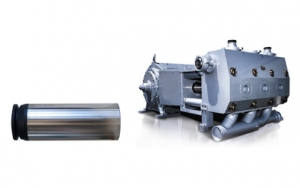

Coatings can be produced with almost an endless selection of materials. The technology of thermal spray, in which the coating process mostly relies on the melting and solidification of a material, allows almost any material that has a stable liquidus range above ambient temperature the ability to become a coating. With so many materials to select from, materials engineering becomes a critical attribute for properly selecting the most advantageous materials to be incorporated in the coating design. As an example, Table 1 shows a list of carbide materials that can be produced into a coating. A coating engineered with tungsten carbide with 12% cobalt is shown in figure 1.

Coatings can be produced with almost an endless selection of materials. The technology of thermal spray, in which the coating process mostly relies on the melting and solidification of a material, allows almost any material that has a stable liquidus range above ambient temperature the ability to become a coating. With so many materials to select from, materials engineering becomes a critical attribute for properly selecting the most advantageous materials to be incorporated in the coating design. As an example, Table 1 shows a list of carbide materials that can be produced into a coating. A coating engineered with tungsten carbide with 12% cobalt is shown in figure 1.

This coating has high hardness, excellent adhesion, and is very dense. It provides excellent wear protection for several different wear mechanisms. However, if the coated component is at an operating condition that has a corrosive media that can attack cobalt such as most strong acids, improving the corrosion resistance of the cobalt binder needs to be done to impede the corrosive attack. The addition of 4% chrome to the binder can greatly improve the binder’s corrosion resistance. In some cases where no cobalt can be tolerated due to the corrosive nature of the media being pumped, substituting cobalt with nickel or even Hastelloy can be a good materials engineering solution. In applications in where the wear surface being protected sees elevated temperatures above 1000°F tungsten carbide can be degraded due to decarburization of the µwear resistance. Substituting the tungsten carbide with chromium carbide will allow for wear protection at much higher temperatures.

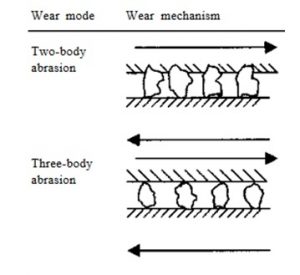

Another coating material that can provide excellent wear protection on pump components, such as mechanical face seals is chrome oxide (see figure 2 at the top of this page). Chrome oxide coatings have very high hardness and work well for many two-body wear applications where hard abrasives get embedded in softer materials that rub against the coating. If the abrasive particles are in a three-body wear mechanism, chrome oxide may not provide good wear protection due to it’s brittle properties. In this case, materials engineering will select wear resistant materials like carbide coatings with metal binders or hard metal alloys.

Finishing of Coatings

Many coated components require surface finishes that are smoother than what can be achieved when the coating is initially applied. Tight part dimensional tolerances may also be required and cannot be reliably achieved with the coating process by itself. Thermal spray coatings can have as-deposited surface finishes as smooth as 60 µin Ra, but more typical as deposited finishes are in the 120-250 µin Ra range. As-deposited thickness tolerances will depend on the thickness of the coating being deposited and the geometry of the part. In general, a coating with a thickness of 0.010-0.015 in will have a thickness tolerance of +/- 0.0015 in. There a variety of ways to achieve smooth surface finishes and tight dimensional tolerances. They include grinding, polishing, hard turning, lapping, honing and other methods. Determining the correct finishing method for a coating is critical partof the coating design. Thermal spray coatings can be produced to have very low porosity which allows them to be finished to very smooth finishes, and smooth as 1 µin Ra and to dimensional tolerances within +/- 0.0001 in.

TST Engineered Coatings

TST Engineered Coatings designs coatings for enhancing the properties of many different industrial components including pump components. When working with TST, our materials engineers will collaborate with the customer to develop a thorough understanding of the environment the coating will be used, and what properties the coating is engineered to achieve. This assures the optimal coating is developed for the specific component and application. Contact TST Coatings if you have any questions about coatings for your specific application.

Comments