Author: Bill Lenling, TST Coatings

Thermal spray coatings are engineered for various industrial components to enhance the performance of the parts-coated surfaces. Properties such as wear resistance, corrosion resistance, and electrical insulation can be engineered into a component’s design with the addition of a coating. In order to determine how to optimize coatings properties, the microstructure of the coating must be understood. This article is an introduction to understanding thermal spray coatings’ microstructures.

What is a Thermal Spray Coating?

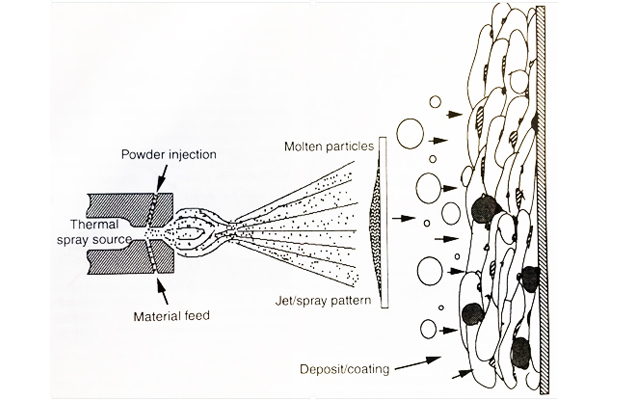

A definition of a thermal spray is the following: “Thermal Spray is generic term for a group of coating processes used to apply metallic or non-metallic coatings. These processes are grouped into three major categories: plasma-arc spray, flame spray, and electric-arc spray. These energy sources are used to heat the coating material (in powder, wire, or rod form) to a molten or semi-molten state. The resultant heated particles are accelerated and propelled toward a prepared surface by either process gases or atomization jets. Upon impact, a bond forms with the surface with subsequent particles causing thickness buildup.”

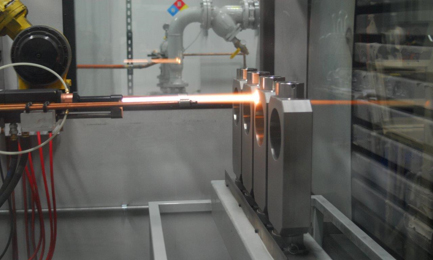

Figure 1 above is a schematic of how a thermal spray process works. As described in the definition, the heat source for melting the powder, wire, or rod feedstock can be generated by electrical energy, plasma-arc, or electric-arc. The heat source can also be through the combustion of liquid or gaseous fuel (flame spray and it subcategories such as HVOF, high velocity oxy-fuel use this process). Figure 2 below shows a part being coated with the HVOF thermal spray process.

Figure 2: Thermal spaying of carbide coating using the HVOF process

Figure 3 below shows a stainless-steel pump housing and rotor that have been coated with a carbide composite coating. The pump is used for pumping food or pharmaceuticals and is made out of an austenitic stainless steel. The addition of a carbide coating to the parts’ design greatly improves its abrasive wear resistance. The coating increases the hardness of the surface from 30 HRC to over 70 HRC after the coating is applied.

Figure 3: Pump housing and rotor that are coated with a thermal sprayed coating for abrasive wear resistance

Coating Microstructures

Understanding a coating microstructure is critical in the engineering of a successful coating. Understanding coating properties such as porosity content, hardness, adhesion, and oxide levels can greatly influence the coating performance.

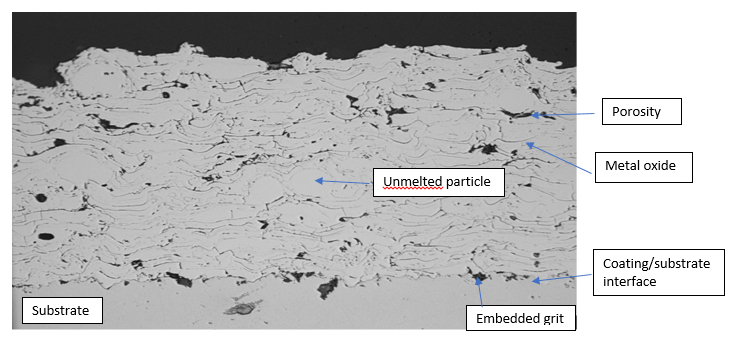

Figure 4 below is a cross-section of a thermal spray metal alloy coating. Those skilled in the art of thermal spray may consider this microstructure of lower quality, but for demonstration purposes, the coating structure shows many of the features that can be found in a thermal spray coating. The coating was deposited using plasma-arc spray. The feedstock material was spherical metal powder.

Figure 4: Cross section and microstructure of a thermal spray coating

Surface Preparation

Before a coating is deposited, the surface of the part being coated needs to be prepared to allow the coating to bond to the surface. This is typically done by roughening the surface by grit blasting. Figure 3 shows a jagged interface between the substrate and coating, which was created by grit basting. This surface morphology allowed the coating to anchor itself by the molten particles conforming and solidifying around the rough substrate asperities. Sometimes, however, grit from the grit blast process can get imbedded into the coating by not being cleaned from the surface prior to depositing the coating. An embedded grit feature can be seen in center of the coating/substrate interface. Normally a small degree of embedded grit does not affect the coating’s performance, but a larger degree of grit can degrade coating adherence to the part.

Lamellar Structure

When a thermal spray coating is produced, the hot molten or semi-molten particles impinge and solidify on the surface forming a layered structure. Upon impacting the surface the particles flatten and solidify in milliseconds, and the coating buildup is known as a lamellar structure. This structure can be seen in Figure 4. An analogy to the lamellar structure is pancakes randomly stacked upon each other.

Oxidation

Most thermal spray coatings are produced in normal, atmospheric conditions. Since oxygen is typically present when spraying metal materials, the molten particles will react with the oxygen and form an oxide layer around the surface of the particle. The oxide layers can be seen between individual powder splats in the coating structure of Figure 3. Controlling oxide content can be a critical attribute in engineering a coating. When a coating is needed to provide corrosion protection, minimizing oxide content is important because corrosive attack of a coating can be accelerated along metal-oxide boundaries.

Un-melted and Semi-melted Particles

When a powder particle is not melted completely in the spray process, it can still stick to the surface, maintain its shape, and get emended into the coating by subsequent buildup of additional molten particles. These features are known as unmelts and can be seen in the Figure 3 microstructure. Unmelts are usually not desired in a coating structure because they are poorly adhered and can cause the formation of porosity. Poorly adhered unmelts can fall out of a coating structure as the coating is attacked by a wear mechanism. Eliminating unmelts is accomplished by proper sizing of the feedstock powder and optimized process parameters for the thermal spray device.

Porosity

Coating porosity is an important attribute that also needs to be controlled when engineering a coating. The porosity in Figure 3 shows up as the dark area in the microstructure. For most coatings, it is desirable to minimize porosity content to maximize coating’s wear and/or corrosion resistance. In some cases, some coating porosity can be beneficial, such as thermal barrier coatings for high temperature protection. In this case, the porosity can provide increased thermal insulation enhancing the performance of the coating.

Composite Coatings

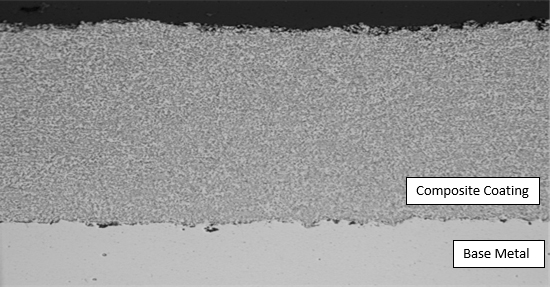

Composite coatings are a commonly produced type of thermal spray coating. An example and cross section of one can be seen in Figure 5 below. This coating is a highly wear resistant coating that is comprised of a ceramic phase, tungsten carbides, and a metallic phase, cobalt. The tungsten carbide is extremely hard and wear resistant. The cobalt wets the carbide and cements the carbide grains together combining to produce a coating with excellent wear resistance and good ductility.

Figure 5: Composite coating, tungsten carbide 12% Cobalt, hardness 1281 Vickers >70 HRC, porosity 0.11%, bond strength > 10,000 psi

Homogenous Coatings

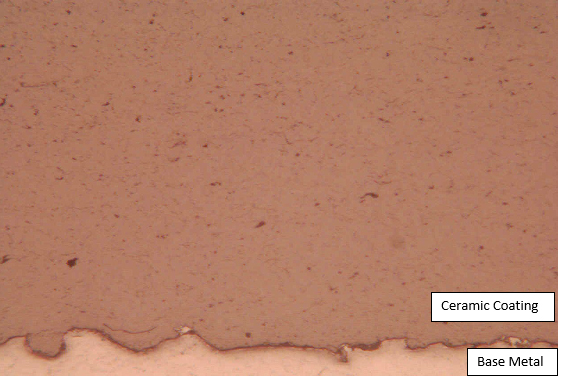

Another coating that is used on pump components, such as mechanical face seals and sealing surfaces on shafts, is chrome oxide (figure 6 below). Unlike a composite coating, chrome oxide is a single phase, homogenous coating containing chrome oxide only. It is very hard, but also brittle. The brittle nature of the coating does not allow it to work well if a component sees impact. It can be very effective for combating two-body abrasive wear if the coating structure is low in porosity and high in hardness.

Thermal spray coatings contain unique microstructures. A detailed understanding of the microstructures is a critical attribute in the engineering of a coating that will perform optimally. Microstructure examination helps provide an understanding on how the coating material and the coating process and process parameters together create the structure. It is an important tool in engineering optimal properties desired to enhance a components performance.

Figure 6: Chrome oxide ceramic coating, homogenous microstructure, hardness 1400 Vickers, porosity content 0.6%

About TST Engineered Coatings

TST Engineered Coatings designs coatings for enhancing the properties of many different industrial components including pump components. When working with TST, our materials engineers will collaborate with the customer to develop a thorough understanding of the environment the coating will be used, and what properties the coating is engineered to achieve. This assures the optimal coating is developed for the specific component and application. Contact TST Coatings if you have any questions about coatings for your specific application.

Very nicely explained about thermal spray coating and its type . The picture or fig 1 in the article makes it simple to understand about how the thermal spray works. Great article.

You have done a great job sharing this great article. I am very thankful to you for sharing all the important information about Thermal Spray. A big thanks for sharing the Schematic of the thermal spray process, although I am not in this field, I like to read new things like this. Thanks for this information, it is really very informative. Do keep Sharing.