The Turbomachinery Laboratory, a center of the Texas A&M Engineering Experiment Station (TEES) and a member of the Texas A&M University System, makes a vital impact in research, education and workforce development. Inside the laboratory facility, students and faculty team up to conduct industry- and government-sponsored research. At the laboratory symposium office, staff work to facilitate extended short courses and symposia, including the annual Turbomachinery & Pump Symposia (TPS).

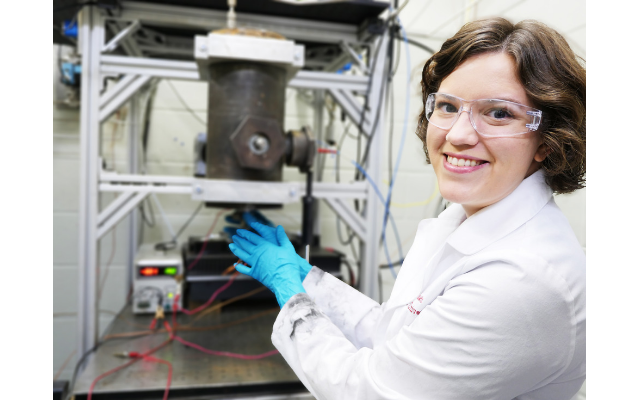

We are honored to share a day in the life of one contributing member of TPS – Catherine Dillier,Graduate Researcher – and this is what she had to share!

Catherine: I fell in love with Texas A&M University my junior year of high school when I visited with a group of friends. Once I was introduced to the many traditions that embody Texas A&M, I was done. Fast forward several years and now here I am working in the propulsion and combustion field, planning on graduating with my doctorate in Mechanical Engineering in December 2020.

I was first introduced to combustion, particularly solid rocket propellants, my senior year of undergraduate when I toured my now advisor, Dr. Eric L. Petersen’s, propellant and energetic laboratory. It opened my eyes to another whole aspect of mechanical engineering, one that really excited me and has now become my passion. I work with solid composite propellant every day, whether I am mixing a new formulation or burning samples. In our lab, we use a combination of micron and nano-sized additives to tailor the burning rate characteristics of solid composite propellants. Each batch and project is slightly different, which presents challenges but also exciting opportunities.

Most of my work days are spent either mixing or burning propellant batches. I always start each day with putting on my favorite music, typically something upbeat and relaxing. This energizes me and prepares me for the upcoming tasks. Testing is definitely my favorite part. We burn all of our samples in a constant volume pressure vessel, igniting them remotely. These tests enable us to study the propellant combustion behavior using advanced diagnostics at very high pressures (up to 10,000 psi). At the end of the day, I hope to pass on what I’ve learned to future graduate students and ultimately make a meaningful contribution to the propulsion community.

Comments