Part 3 in (A Series of) Reasons to Choose AODD Pumps

Author: Mark A. Johnson

I have always used the word “prescribe” rather than “suggest” or “recommend” an AODD model for an application. Just as when you go to the doctor and they diagnose your ailments, they ask a series of questions and take a series of measurements or readings (weight, height, temperature, blood pressure, etc.) and then diagnoses your situation. Not that I am comparing what we do to a doctor, but the process is the same. We ask, “What’s problem you are trying to solve (pump a fluid from point A to point B)?” and “What are your symptoms (high flow, low head, variable pressure)?”. Then we have lots of tools at our disposal to ‘diagnose’ the application and prescribe a solution.

In future articles, I will talk about chemical resistance and materials of construction, but for today, I would like to help you understand AODD pump curves, what information is available (based on the duty point), and how we prescribe a pump model for an application.

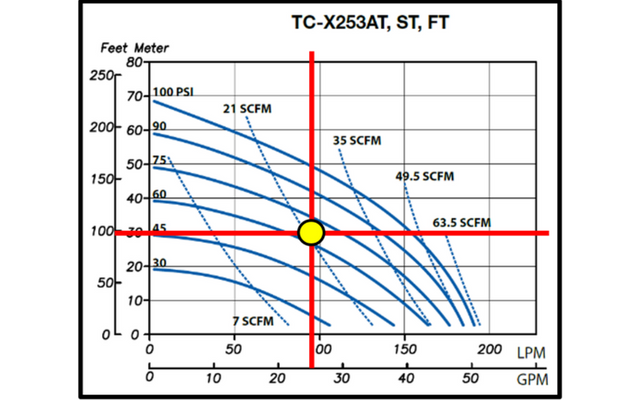

Let’s start with this sample inquiry – “I need to pump a runoff sump of rainwater (the problem we are going to solve) up 100 feet to a storage tank and would like to do it at about 25 Gallons Per Minute (the “symptoms” of their application)”. Notwithstanding the need to evaluate materials of construction based on chemical compatibility and the fluid characteristics, we would like the pump curves to see what size or series of pump we would need to prescribe an appropriate solution. Based on these symptoms, a 3/4” metallic pump could be one of the options, so I will use this curve based on where the duty point falls – most favorably in the middle or sweet spot of the curve (more to come on that later).

Based on the input received, we find the head pressure in feet (100’) and then the requested flow (25 GPM); where they intersect is the duty point. We would definitely prescribe this pump series (the Iwaki AIR TC-X253 Metallic Series) as the duty point is in the middle of the curve for best performance and parts life expectations.

Based on that duty point, when you follow the solid blue line back up and to the left, you will see it is about half-way between the 60 and 75 PSI lines – so you would need about 68 PSI inlet air pressure to the pump to get it to perform at the required duty rate.

Secondly, when you follow the dotted blue line upwardly, you see it is just a ‘smidge’ over 21 SCFM – so we would say you need at about 25 SCFM from your compressor to meet the requirements of the required duty point (read my previous article about PSI vs. SCFM).

Hope this helps! Remember that the pump curve is but one tool in the pump selection process – more to come on those tools in the very near future.

Learn more at www.IwakiAir.com.

the dotted blue line, what is the minimum air consumption, if I need 50gpm with 15feet, so this pump series cannot work? since no dotted blue line there,

Hi Aisyah, since the duty point you specified falls between two SCFM dotted lines, you could average the two numbers and estimate the required SCFM or you would look to use a smaller pump that fits more into the heart of the curve (not too far out to the bottom right or top left). The curve presented is for the 253-Series which is 1″ so you could look at the 1/2″ or 3/4″ size pumps for a better fit.