Stan Riddle, VibrAlign

When I started in maintenance, cutting shims for alignment was commonplace. Today, there are many different sizes of commercially available, pre-cut, stainless steel shims. You can even special-order shims to almost any size and thickness.

But sometimes…you gotta do what you gotta do! So, if you MUST cut shims, here’s some friendly advice.

MATERIAL

- Stainless Steel – highly preferred, since it’s hard enough, doesn’t rust, and is stable.

- Brass sheet – a decent second choice. It doesn’t rust, but it deforms much more easily.

- Carbon steel – a terrible third. Stay away from using carbon steel if possible.

- There is no good fourth place. Not aluminum, wood pallets, washers, drink cans, all-thread, nuts, cardboard, plywood…etc.

SIZING

- Know the thickness you need, and order stock accordingly.

- Measure the length and width of the foot. The Shaft Alignment Handbook recommends that the shim cover at least 80% of the foot area. Make the shim at least a half-inch longer on one dimension, so you can place it, and remove it as needed. If you’ve ever struggled “fishing” shims from underneath a foot with needle nose pliers, you understand why.

- Cut more shims than you think you will need, because you will probably need them too.

MACHINING

- Layout the shim. Saw or cut it out with a cutting wheel. If you have a milling machine available mill it out. If you must burn it out, use a plasma cutter. An acetylene torch will distort the plate. A sheet metal shear will leave a burr, so deburr it.

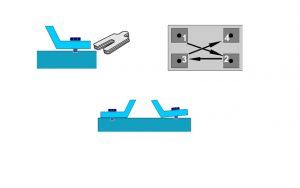

- If you drill a hole for the bolt, slot it, so the shim can be slid in without removing the bolt.

- De-burr it well, peen it flat (if needed), and file or stone it, to make it as flat as possible.

FINAL THOUGHTS

- Measure the shim thickness with a micrometer, and write the thickness on the shim with a permanent marker. It’s also a good idea to write down the name or number of the machine it is for.

- Get a storage box or drawer for your custom-cut shims, so you can keep up with them, and re-use them in the future.

Cutting shims is a hassle, time-consuming, and a good way to get cut! But sometimes you may not have a choice. If you must cut shims, be safe, accurate, and smart.

Comments