Author: Stan Riddle, VibrAlign

There are two types of shaft misalignment – offset and angular, and there are two types of soft foot – offset and angular. And just as you cannot properly align couplings without correcting both offset and angular misalignment, you cannot effectively correct soft foot without correcting both the offset and angularity.

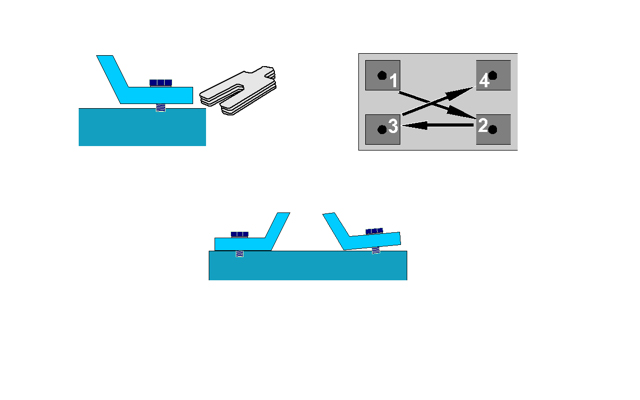

Offset, or parallel soft foot is a rocking motion, almost always diagonally, like a chair with one leg too short. And it doesn’t matter if the soft foot is on the motor, or in the base, it must be corrected.

To correct an offset or parallel soft foot, loosen all four motor feet. Using a 5 mil (0.005”) shim or feeler gauge, check for a gap under each foot in at least three corners. Add shim as necessary to fill in the gap.

Repeat this process for the other three feet, then retighten all four feet. Remember, the motor feet should be tightened in a controlled, repeatable pattern, much like a pipe flange or head gasket. Follow this pattern each time all four feet are loosened and tightened.

Angular soft foot is most often caused by either a bent foot, or a base that isn’t flat. To correct an angular soft foot, you must isolate it. Loosen only one foot. Using a 2 mil (0.002”) shim or feeler gauge, carefully measure in at least three corners of the foot. Add shim as necessary to correct the angular soft foot. It may be necessary for you to cut a partial shim to fill the gap properly. Tighten, and repeat for each foot.

After soft foot has been minimized, proceed with your alignment as normal. You will find that the repeatability of your alignment measurements will increase dramatically, and your alignment should only take one or two moves to correct.

Comments