In the metalworking industry, CNC machines and lathes require fluid to reduce heat and promote tool life during the process of cutting metals. There are different ways or methods to deliver coolant to the cutting tool—flood cooling, medium pressure, and high pressure. Hydra-cell pumps are mainly used in high-pressure coolant delivery systems, which require a positive displacement pump or a multi-stage centrifugal pump that is pumping fluid through the rotary union of the CNC machine into the tool.

On the drilling side of the bit, the fluid is directed to the appropriate point at the intersection of the tool and the product being drilled. Coolant at a high pressure will cool the tool and promote tool life. It also increases productivity by allowing drilling at a much faster speed while evacuating chips from the cutting area.

Hydra-Cell Seal-less pumping technology is perfect for this application for many reasons, including:

- It meets flow-pressure requirements with accurate flow control for no loss in efficiency, especially when using a Variable Frequency Drive (VFD) Controller. A VFD controls pump speed allowing the system to maintain necessary flow rates to generate the required discharge pressure for the process.

- It handles abrasives and particulates so there is no need for fine filtration for the pump. Most pump technologies require filtration to the point of very small micron particulates. Hydra-Cell pumps do not require this.

- It can pump non-lubricating to high-viscosity fluids. Machine tool coolants can be oil-based or water-based. Water-based coolants can often lose their lubricating characteristics. Other pump technologies (screw pumps, gear pumps, and centrifugal pumps) require lubricating fluids because they have tight tolerances between the gears, screws, and sealing surfaces that require lubrication.

- Hydra-Cell Seal-less pumps eliminate that requirement of lubricating fluids due to the spring-loaded valve and valve seat design.

- It can run dry and under high inlet vacuum without damage. Pumps with tolerances cannot run dry or under high inlet vacuum without costly damage to the pump. Hydra-Cell Seal-less pumps can run dry which offers a substantial advantage.

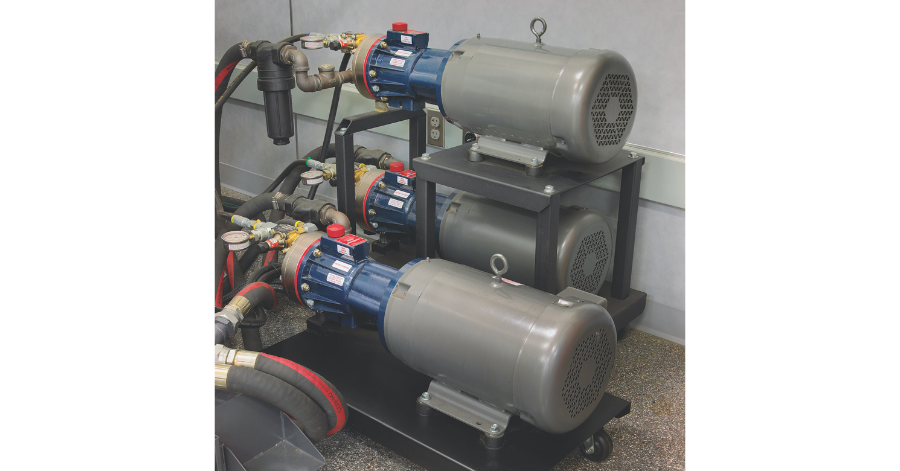

- It has a compact size to integrate into systems. Sometimes the footprint is small for a pumping system. Hydra-Cell Seal-less pumps can fit into compact spaces.

- It is energy efficient. Hydra-Cell Seal-less pumps are 95% efficient compared with 60 to 70% efficiency of other pumps.

- There are no cups, packing, or seals, which offers minimal maintenance.

Hydra-Cell Seal-less pumping technology is commonly used for high-pressure machine tool coolant systems. They compete with piston pumps, screw pumps, gear pumps, and multi-stage centrifugal pumps, however, the seal-less feature of Hydra-Cell pumps offer a particular advantage, especially with regard to running dry, low maintenance, and high efficiency. Hydra-Cell Seal-less pumps are used by many of the major CNC machining companies.

Hydra-Cell pumps are available in several models featuring a wide range of flows and pressures for a variety of applications. Ten seal-less Hydra-Cell models are equipped with metallic liquid ends that are ideal for the delivery of high-pressure machine tool coolant. Eight models have a horizontal configuration, and two models have a vertical configuration.

Hydra-Cell pumps are available in several models featuring a wide range of flows and pressures for a variety of applications. Ten seal-less Hydra-Cell models are equipped with metallic liquid ends that are ideal for the delivery of high-pressure machine tool coolant. Eight models have a horizontal configuration, and two models have a vertical configuration.

For more information, please visit https://www.hydra-cell.co.uk/media/MachineTool/HydraCellIntelligentHighPressureCoolantPump.mp4

Comments