Author: Rich Muraca, National Business Development Manager, Packaged Solutions, WEG Electric Corp.

Since 2006, a global pump manufacturer has partnered with WEG Packaged Solutions to remain responsive to the needs of equipment owners and contractors around the world. Maintaining a broad product line of both diesel and electric pumps, this large OEM provides pumping equipment used for dewatering and liquids transfer in municipal and industrial applications. Offering options for purchase or rental, this major OEM supplies pump packages that are rugged, durable, and most importantly, portable.

The Portable Packaged Solutions engineered by WEG have enabled the Pump Manufacturer to realize:

Shorter Lead Times – The OEM had originally sourced components from Germany, but WEG uses their local supply network to provide portable VFD packages and TEFC motors with faster turnaround times; enabling the OEM to reduce their lead time from 12 weeks to 8 weeks. Whether the pump manufacturer requires 100 units or only 2 at a time, WEG Packaged Solutions provides what is needed *when* it is needed. Using WEG’s streamlined ‘smart part’ order system, this large OEM has all the information they need to create a client quote without extra interactions with the WEG team – saving time and expediting the process.

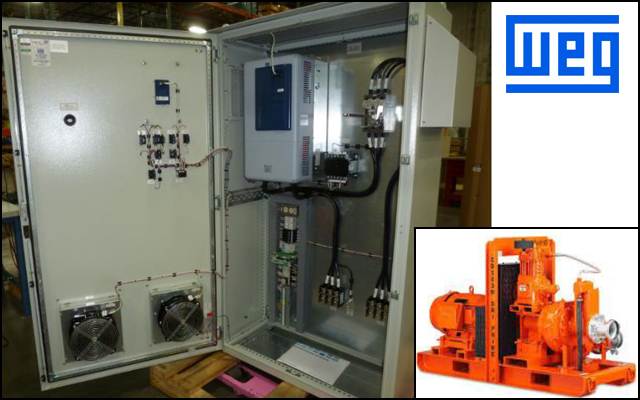

This large pump OEM currently obtains the following packaged solutions from WEG: (left) Frame 1 is comprised of a NEMA 3R enclosure and contains a CFW11 Variable Frequency Drive rated from 25HP up to 175HP, 460-volts; (middle) Frame 2 is comprised of a NEMA 3R enclosure and contains a CFW11 Variable Frequency Drive rated from 200HP up to 600HP, 460-volts; (right) Frame 3, currently in development, will utilize a NEMA 3R enclosure with a CFW11 Variable Frequency Drive rated from 700HP up to 1,000HP.

Enhanced Safety – safety is a priority for every manufacturer. This is why engineers at WEG implement safety options into every NEMA 3R enclosure – safety options which include: enclosed switches that could be vertically and horizontally adjusted to fit the frame size; a UL-certified voltage monitor that meets OSHA standards and enables technicians to more safely verify and measure voltage from outside the electrical cabinet; and Arcflash Reduction Maintenance Breakers that minimize arc flash energy.

Engineered Design Improvements – having a long-term relationship with this pump manufacturer allows WEG to upgrade the portable VFD packages based on the OEM’s experience and feedback. Over the years, the robust VFD packages have evolved to include: a new cooling system that relies on roof ventilation, a metal mesh filter, and two centrifugal fans to increase air flow and achieve maximum cooling for reliable operation in locations exposed to hotter temperatures; a new cage design with corrosion-resistant hardware; rack systems to make it easier to lift the VFD packages during installation and removal; shock mounts on the racks to minimize vibration and extend equipment life; and a user-friendly HMI touch screen for easy set-up, programming, and monitoring.

This major manufacturer is known for providing reliable pumping solutions, and they rely on WEG to supply safe, high quality packaged solutions to keep their equipment running and their customers happy.

Check out the 2018 WEG Automation Catalog!

About WEG Electric Corp.

Founded in 1961, WEG Electric Corp. has grown into a global solutions provider of industrial electrical technologies. WEG is the largest industrial electric motor manufacturer in the Americas and one of the largest manufacturers of electric motors in the world producing over ten million units annually. Committed to growth on a global scale, WEG continually invests in state-of-the-art manufacturing facilities and processes, and the development of new and improved industrial electrical solutions. WEG offers a diverse and integrated product line that includes motors, drives, controls, transformers, generators, and packaged solutions.

Comments