Growth, Trends, Opportunities and Forecasts

Growth

The water and wastewater treatment equipment market is growing at a CAGR of 7.4%, with huge growth expected at the end of this decade.

Trends

- M&A activity among EPCs picks up, signaling water industry consolidation

- Investments in infrastructure increase

- Drought and environmental concerns renew interest in water reuse and desalination

Source: Bluefield Research

Reuse & Desalination

Municipal wastewater reuse will increase by 61% by 2025, requiring $11 billion of capital, according to a 2015 report by Bluefield Research. With more than 247 reuse projects currently in various stages of planning in the U.S., this is a key market trend. Despite being enormously expensive and using significant energy resources, desalination will also continue to be a part of the water treatment conversation with roughly $21.4 billion spent on this technology in 2015—an investment that is expected to reach $48.2 billion by 2020.

The Global Picture

Rapid growth for the water treatment equipment market is driven by growth in global water demand. Water shortages are experienced in many regions of the world and will be a major global issue by 2025. This is due to:

- rapid population growth

- changes in lifestyle

- increased infrastructure activities

- pollution that contaminates fresh water resources

Disinfection, filtration, and desalination are expected to grow in Asia-Pacific. Australia, China, and India with high investments in the desalination process.

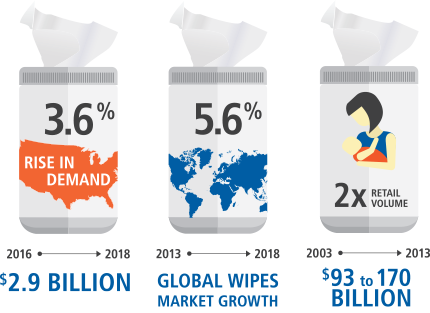

As consumers seek convenience and cleanliness in a quick-and-easy “disposable society,” more people are using wipes today than ever before. “Flushable” and personal care wipes have seen consistent growth worldwide over the past decade with no signs of a slowdown.

- More than 50% of U.S. Municipal water/wastewater infrastructure is nearing the end of its useful life.

- EPA Survey: $271 billion investment required to improve infrastructure over next 5 years.

- Municipal water reuse to increase 61% by 2025 requiring $11 billion in capital.

- $550 billion to be invested between 2016 and 2025 for capital improvements to replace deteriorating pipes, sewer overflows, etc.

It’s clear that wastewater facilities have to invest in new pumps, so it is critical that these new pumps have the capability to address the challenges wastewater plants face on a frequent basis – which, in today’s world, is clogging.

How can wastewater facilities ‘conquer the clog‘?

Consider the advancements made in the area of pump hydraulics. There are some pumps designed with specially engineered impellers that allow successful fluid flow throughout a wastewater plant. For example, KSB has a full range of Next Generation Impellers that fit virtually any pumping condition.

Compare wastewater pumps currently available to the market. DOWNLOAD THE WASTEWATER PUMP COMPARISON CHART, which lets you quickly compare the KSB Amarex KRT with competing technologies.

Comments