In the case of wastewater treatment plants, inflows can vary according to the weather or season. The new TRE 312 product family rounds off the Wilo slow-speed product portfolio with a nominal propeller diameter of 1.2 metres. The new TRE 312 submersible mixers are mainly used with fluctuating water levels (SBR), in MBBR processes, and in smaller activated sludge tanks. The new series is also suitable for unrestricted continuous duty.

The series is thereby proving to be extremely efficient, as the Wilo Product Manager explains: “Thanks to an optimum thrust output figure due to the standard installation of an energy- efficient IE3 motor (in accordance with IEC 60034-30), and the innovative blade geometry, the newly developed mixer is particularly economical,” says Thomas Tschanter, Product Manager for sewage treatment technologies at Wilo. “As a result, operating and energy costs are kept at a low level. At the same time, we are nevertheless able to guarantee a high level of operational reliability.” The backward-curved incoming flow edge of the propeller also provides reliable protection against unwanted clogging and thereby ensures the uninterrupted operation of the Wilo-EMU TRE 312.

“We made the propellers out of polyamide plastic in solid material. This material is considered to be extremely low-wearing and ensures the long service life of the product. Using polyamide in solid material makes the three-blade propeller with a nominal diameter of 120 centimetres less vulnerable and thus reliably protects the mixer against abrasion,” clarifies Tschanter. Installation is also very convenient, since the Wilo-EMU TRE 312 mixer is already delivered ready for installation with fully mounted propellers.

In order to get the right impression of the product in advance, Wilo, as a system expert for wastewater treatment technology, is offering its customers support with the design phase and configuration through to the maintenance concepts – i.e. individual, tailor-made solutions across all phases of the project. The unique “Try & Buy” service is also available for the Wilo-EMU TRE 312 submersible mixer.

It can be tested without any obligation for up to six months before buying. This gives customers an accurate picture of the quality, ease of installation, and efficiency – a decision without any investment risk.

Wilo is a premium system partner in the field of water management. The Dortmund-based company offers innovative all-in-one solutions for water-supply units, sewage pumping stations or wastewater treatment plants. From design work, via project supervision to installation and maintenance, everything comes from one source. State-of-the-art technology, systems and services are interconnected to make day-to-day work as efficient and simple as possible.

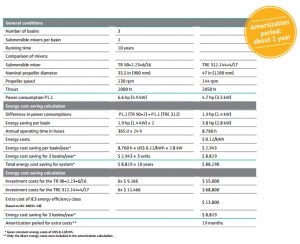

The Wilo TRE 312 submersible mixer enables you to save energy costs. The new blade geometry and the highly efficient submersible motor ensure outstanding energy efficiency – even in energy-intensive continuous duty. And as the annual overall saving shows, the thrust required here can also be cost-effective.

The Wilo TRE 312 submersible mixer enables you to save energy costs. The new blade geometry and the highly efficient submersible motor ensure outstanding energy efficiency – even in energy-intensive continuous duty. And as the annual overall saving shows, the thrust required here can also be cost-effective.

Download the 4-page document to review the Cost Savings that can be achieved.

Learn more at www.wilo-usa.com.

Comments