Problem: The City of Manchester, NH WWTP utilizes an activated sludge process for treatment and a fluidized bed incineration system for sludge disposal. To fuel the system the plant used a progressive cavity pump to feed a mixture of sludge, grease, scum, and occasionally oil, to the incinerator.

The plant has a 60% combined sewer and in the spring there is an excessive amount of bark mulch that ends up in the plant scum and causes progressive cavity pumps to clog. The plant tried in-line grinding, but even the grinders got plugged. They also tried hose pumps and again the scum/grease/bark mulch mixture clogged the inlet. According to the operators, it has been a nightmare since the incinerator went online in 1994.

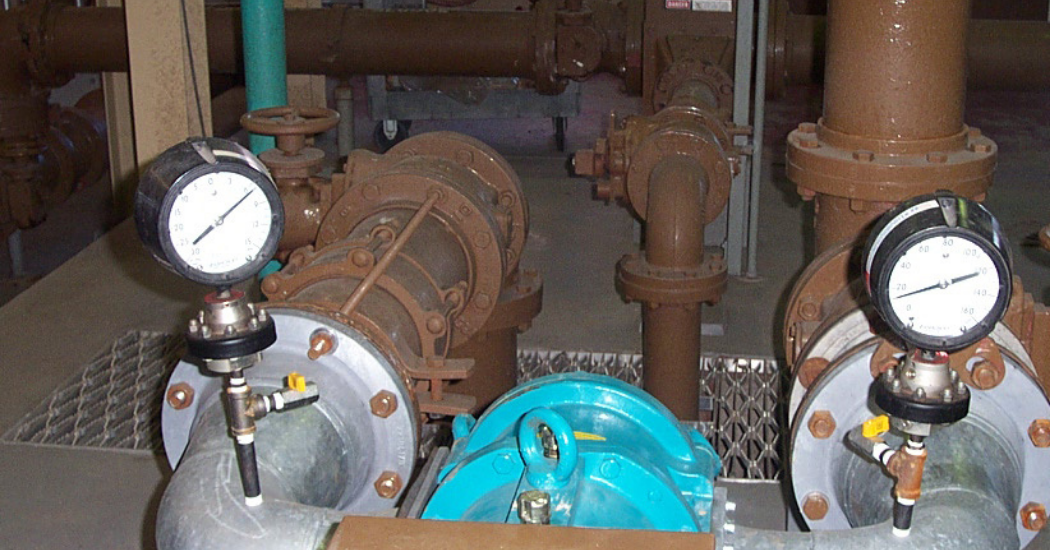

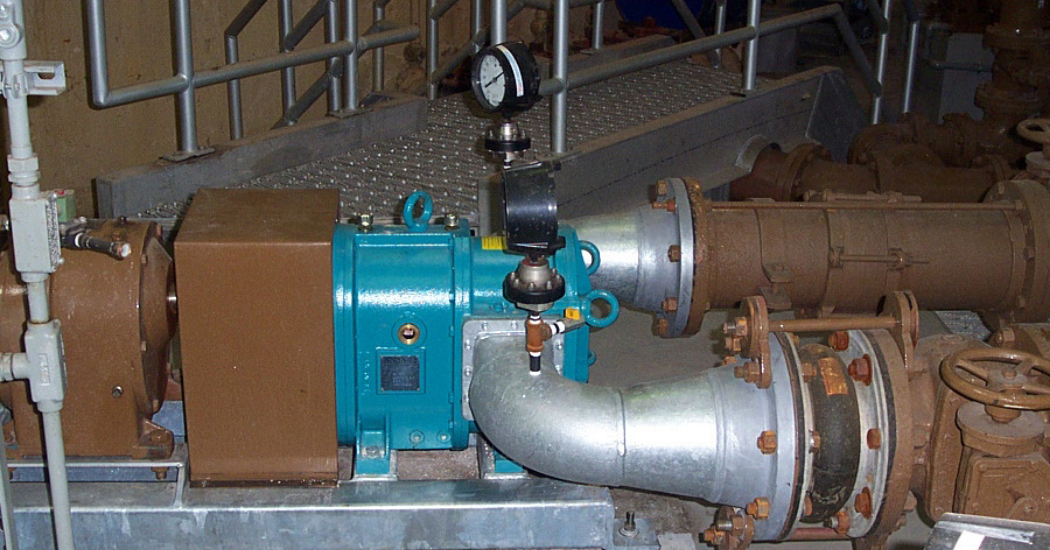

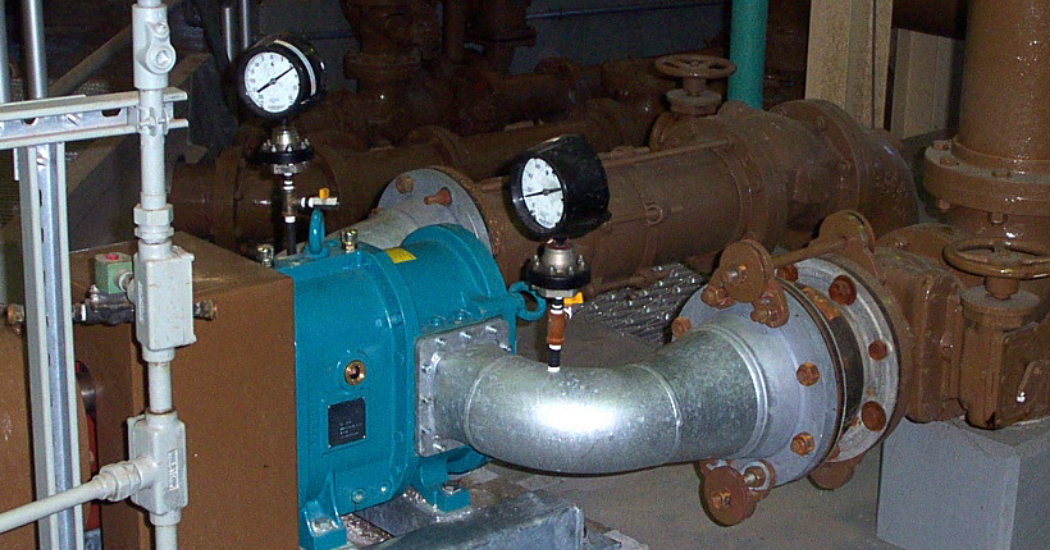

Solution: The plant installed a trial Boerger PL200 over-sized, side-mount pump with a large square inlet port so the product could drop directly into the lobes without any restriction.

Result: Where no other pump worked the Boerger PL200 trial pump successfully feed scum to the incinerator at 2rpm. After seeing this success, the Manchester plant purchased one to install permanently. 612-435-7300; www.boerger.com

Read another success story of Boerger pumps!

Comments