DFT Inc. had been contacted by a major engineering firm from the Northeastern region of the US with an inquiry about a check valve solution for a waste drain in a pharmaceutical / medical application.

Understanding the Application

The check valve would be used for medical non-corrosive waste that would be pumped through a drain to a waste drain, with no more than 10 psig at temperatures up to 300F° and low flow of 3 GPM. The line is then flushed with utility water into the waste inactivation line with a duration of 10 minutes flush at 5 GPM. The line is then steam sanitized with clean steam and condensate forced into the waste inactivation line at 330F° at about 30 psi for about 60 minutes. The line is then air dried with compressed air for about 30 minutes at about 20 PSI. This procedure is repeated at least 3 times a day.

The Requirements

It was important for the new check valve to meet the following criteria:

- Sanitary connections were needed;

- the ability to steam clean in place was required;

- low cracking pressures

- tight shut off

The Solution

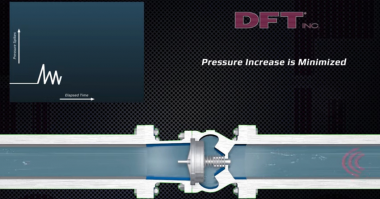

A DFT® 2” model DSV® Check Valve was used to meet the criteria. It is a non-slam spring-assisted check valve designed to prevent flow reversal in industries with strict cleanliness codes. The 2” DSV can be used in a Vertical Position, able to be equipped with a .1 psi cracking spring, is steam cleanable, and is a full body valve with Tri-clamp connections. This check valve was able to withstand the frequent cycles and has been in operation since 2009.

Learn more about Sanitary Check Valves!

Comments