Author: Jeff Kane, DFT Valves

Before you buy a check valve, you should have a clear understanding of the way valves work and how they might impact your application. Here are some key considerations about check valves that all engineers and maintenance managers must know.

- Check valves are an essential element in the design of an efficient pumping system.

- Check Valves should be sized for their application and flow, not based just on pipe diameter.

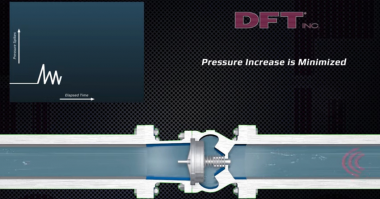

- Water hammer is a direct result of a pressure surge or wave caused when a fluid (usually a liquid or slurry) in motion is forced to stop or change direction suddenly.

- Water hammer can be significantly reduced with the correct choice of check valve.

- An undersized valve will cause high pressure losses and create excessive noise and vibration.

- An over-sized valve can lead to premature wear and failure of the valve’s internal components.

- Properly sized check valves can dramatically add to the life of the valves as well as longevity of pumps and other related components.

- An energy efficient check valve is a properly sized check valve in a pump fluid flow system that allows the required flow, while minimizing energy consumption.

- Low flow application check valves should be sized so the valve is fully open based on maximum flow.

- Metal sealing surfaces generally will allow some leakage while elastomers (soft seats) such as Buna-N and Viton provide bubble-tight shutoff (zero leakage).

When used properly and for the appropriate projects, check valves can offer many benefits. Understanding their capabilities proves an essential part of utilizing them toward the success of your system. To find out other key considerations when designing fluid or Gas flow Systems, download our Design for Flexibility eBook.

Valve Value: The Return on Investment (ROI) of Quality Check Valves

Comments