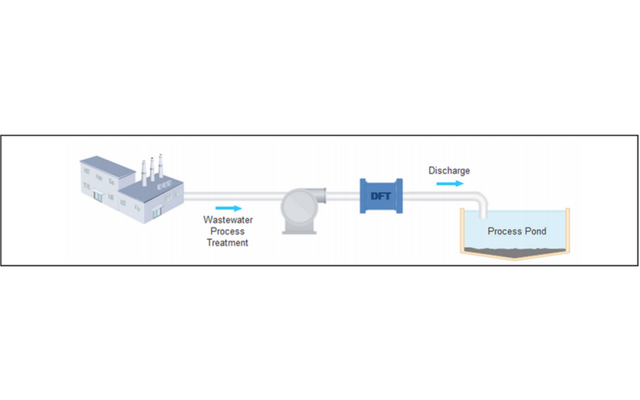

A large refinery in the Ohio Valley was experiencing severe water hammer with swing check valves installed in their waste water process treatment system. The swing checks were installed in a pump discharge configuration with a long vertical pipe run after the valves. Operators said that when the swing check valves were installed, the ground would shake due to the severe water hammer caused by the valves cycling. The swing checks had repairs performed on them every year to replace the internals of the valves.

The DFT® model Excalibur® was the solution to their problem. Two – 16” 150# WCB/SS Excaliburs were installed in 2004 and one was replaced in 2013, giving the company 9 years of maintenance free service. Operators at the refinery commented that when the Excaliburs cycled it made a click noise compared to the boom noise caused by the swing check valves cycling. DFT® Model Excalibur®

- 2” to 24” line size*

- ASME class 150 to 1500

- RF & RTJ flanged ends, butt weld ends

- ASME B16.10 face-to-face dimensions

- Stainless steel trim • Center-guided/dual-guided stem

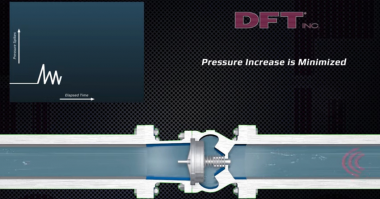

- Spring assisted silent closing, non-slam

- Tight shutoff – lapped disc & seat

- Two-piece body

- Horizontal or vertical installation

*For larger sizes, contact DFT

Comments