Overview

Sewage backup and overflow issues are a problem; even more so when the overflow is coming into your home. This Baltimore inner harbor residence’s building location prevents a traditional wet well due to the high water table. As a result, ejector pumps are located on the lowest level, the parking garage. Eleven lift stations throughout the complex use retention tanks that often clog and spill sewage into the garage surrounding resident’s vehicles with an odorous and hazardous mess.

Clean-up, sanitation, and repainting of the location are required with each overflow event. Factors such as garage ceiling height, door size, and ramp access make the clean-up efforts difficult and costly; but most importantly, it is disruptive and potentially hazardous for the building residents. The building owners require a pumping system that solves all of their problems – invisible to the residents and aligned with their commitment to providing a safe and healthy environment.

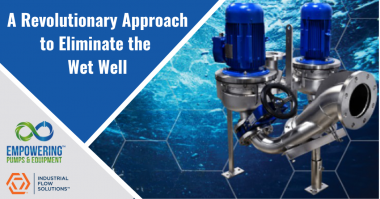

OverWatch™ Direct In-Line Pumping is the solution.

Solution

The OverWatch™ system eliminates the need of a wet well and lifts effluent directly from the inlet. With no detention time, pumped materials are handled as they arrive and are unable to solidify. Unlike batch pumping of traditional systems, the OverWatch™ pumps can maintain clog-free operations andprevent the retention tank overflowing into the residents parking garage.

Building owners were not only impressed by the elimination of odors and reduction of the pump machine noise – a huge improvement for their residents, but they also appreciated the reduced machine size which allows for additional access space in the existing pump area.

With the success of the initial installation, the building plans to replace each of the existing 10 pump stations annually with the OverWatch™ Direct In-Line Pumping system.

Features

- Reduces maintenance cost and energy consumption

- Eliminates the wet well and associated hazards

- Constant monitoring and smart machine operation eliminates blockages/backups

Applications

- Retrofitting of current wet wells

- New pumping stations where excavation depths required is difficult or expensive to achieve

- Replacing pumps prone to ragging/clogging

- Areas where sewage odors are unpleasant to its environment

- Ejector pumps with high concentration of Fats, Oils, Greases

Comments