What Are ‘Murphian’ Particles?

“There’s a particle size that’s well-known in the slurry transport industry as the Murphian particle size,” explains Reab Berry, resident slurry expert at GIW. “In the world of slurry pumping, it is, without a doubt, a very difficult particle to pump.”

“There’s a particle size that’s well-known in the slurry transport industry as the Murphian particle size,” explains Reab Berry, resident slurry expert at GIW. “In the world of slurry pumping, it is, without a doubt, a very difficult particle to pump.”

The perfect particle to pose a problem

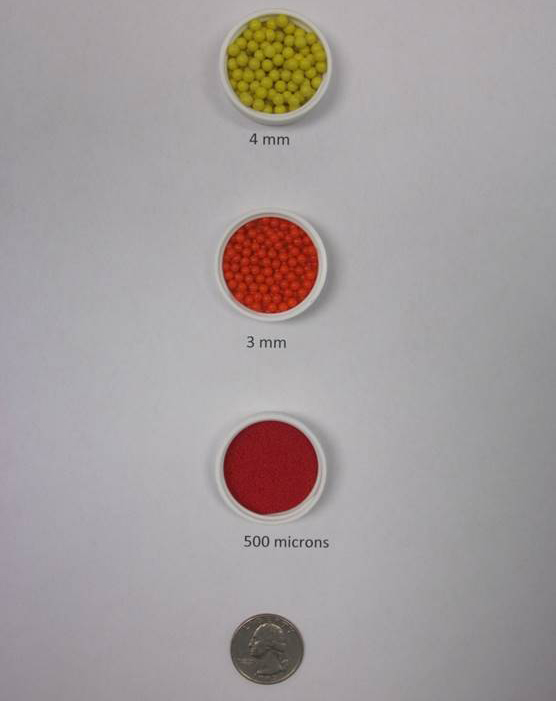

What makes this 500-micron particle such a challenge for slurry pumping experts around the globe?

As Berry explains, the Murphian particle is the perfect size to get stuck in the laminar boundary layer that exists inside all slurry pipelines.

“There’s a laminar boundary layer around the inside of pipe that happens to be about 500 microns thick, and the Murphian particle gets trapped in that layer,” Berry says. “It’s too small to stick up out of the boundary layer and get pushed along by brute force, and it’s too large to get kicked up out of the boundary layer into turbulent suspension like particles smaller than 500 microns, so it just gets trapped.”

To better understand how this happens, take a look at the GIW-produced video above that shows how Murphian particles can cause difficulty in slurry transport pipelines.

Finding a solution

Clearly, Murphian particles can present significant problems in pipelines. Luckily, you can adjust the transport velocity to avoid these issues.

So, how do you know what velocity to use if you pump significant amounts of this 500-micron material?

Comments