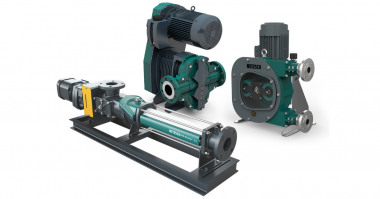

NETZSCH Pumps North America will be showcasing its dewatering pumps and skids at the Society for Mining, Metallurgy & Exploration (SME) Annual Conference & Expo 2019, February 24-27, 2019, Denver, CO, Booth #2050. Stop by the booth to see a fully functioning dewatering skid featuring the latest NETZSCH technology. Also to be highlighted is the line of NEMO® progressing cavity pumps, the NOTOS® Multi-Screw pump for mining, and the TORNADO® T2 rotary lobe pump.

Stop by the booth to see safe, reliable and cost efficient NETZSCH mine dewatering pumps and pump skids ideal for mines that require a small and compact movable unit to address their dewatering challenges. The base unit includes a tank, progressing cavity pump with right angle gearmotor, inspection ladder, valves, and piping all mounted on a common galvanized steel skid. Also available are optional units with a control panel (with or without VFD on a removable stand) and instrumentation, including high/low level switches for the tank or dry run protection for the pump. Individual pumps are available to retrofit existing skids.

The tank includes baffle/divider screens to filter out any solids too big to fit through the pump. The pump is located to the side of the tank, enabling easier access and maintenance. The standard unit uses a right angle gearmotor to save space and eliminate the need for a belt drive, with belt and pulley designs also available. Operator safety is enhanced by the inclusion of a removable inspection ladder with hand rails and a removable safety screen for the tank.

Available in a wide range of flow and pressure capabilities, the pump and tank can be constructed from elastomer, carbon steel, stainless steel, galvanized steel, and Halar/rubber-lined steel, depending on application needs.

Visitors to the booth can also learn about the NEMO® progressing cavity pump, known for its continuous, pressure-stable, gentle and low-pulsation conveyance of almost any process fluid without being affected by fluctuations in pressure and viscosity.

Also on display will be the NOTOS® Multi-Screw Pump for mining, designed to convey shear sensitive or chemically aggressive media. It features a long service life, low pulsation continuous flow, and more.

The self-priming, valve-less TORNADO® T2 rotary lobe pump will also be highlighted. The TORNADO® T2 offers maximum operational performance, high reliability and durability, ease of maintenance, and a low total life cycle cost. With a revolutionary design that has been recently reengineered to maximize uptime, the TORNADO® T2 pump, features metal lobes running inside a metal housing with an elastomer liner.

Comments