Anglo American changes to Sulzer dewatering pumps for major iron ore mine site in Brazil. Sulzer pump specialists have helped global miner Anglo American overcome persistent reliability problems at an important iron ore project in Brazil. Since the switch to Sulzer’s range of advanced dewatering pumps, the site has experienced improved reliability and reduced spending on spare parts and maintenance.

Producing since 2014, Anglo American’s Minas-Rio is a fully integrated iron ore export operation in the Brazilian state of Minas Gerais. Ore from the mine is processed on site and transported via a 529 km pipeline – the longest in the world – to an export terminal at the port of Açu in the state of Rio de Janeiro. At full capacity, Minas-Rio is expected to produce 26.5 million tons of ore per annum. Estimated reserves at the site are 1.45 billion tons and the mine has a planned working life of 45 years.

Searching for improved performance

Like most open cast mines, rain and groundwater can accumulate in depressions across the site. Operators use submersible dewatering pumps to remove this water, keeping working areas clear. When the mine first opened, however, the abrasive nature of the water, which contains high levels of debris, resulted in rapid wear and frequent pump failures. Repairs were expensive and time-consuming to complete.

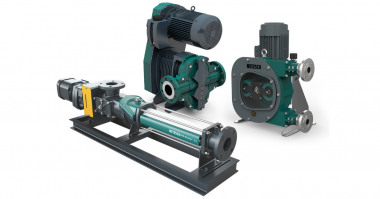

Six years ago, the mine’s operators made the decision to seek an alternative pump supplier. After a comprehensive survey of the market, the operator selected Sulzer as its preferred supplier of dewatering pumps for the site. The company’s range of dewatering pump uses a modern design, tailored specifically for the challenges of mining operations. The pumps use wear-resistant components and have a modular design that makes the replacement of damaged components quick and simple.

For Anglo American, the Sulzer proposition offered additional benefits too. Sulzer’s main service center is only 100 km from the site, simplifying service and support logistics. In addition, under the terms of a long-term service agreement, Sulzer maintains an agreed stock of spare pumps and service parts, reducing operating expenditure for Anglo American. Today, more than 80 Sulzer dewatering pumps are in operation across the mine.

Superior flexibility

The Sulzer pumps are also equipped with premium efficiency IE3 motors. While not a requirement for submersible pumps, these motors consume less energy than lower-spec alternatives and their cooler running helps to prolong the life of critical pump components.

Mine dewatering operations require highly durable pumps, but they demand maximum flexibility too. Pumps are relocated repeatedly during their working life, and they need to work efficiently at a wide range of different heads and flow rates. Those requirements also evolve during the lifetime of the mine: as work gets deeper, pumps need to generate higher heads.

With these changing long-term needs in mind, Anglo American has recently invested in two of Sulzer’s award-winning XJ 900 high-capacity dewatering pumps. This innovative design features twin impellers that can be configured to operate in parallel to produce maximum flow, or in series for high-head applications. Switching between the two configurations can be achieved quickly and easily by flipping two internal components.

XJ 900 high-capacity dewatering pump

Long-term reliability

At Minas Rio the XJ 900s will initially be operated in their high-flow configuration, then switch to high-head operation as the mine gets deeper. The pumps can deliver a maximum flow rate of 120 l/s in high-flow configuration, and a maximum head of 230 meters with the impellers running in series. Long-term protection of the pump is ensured by an advanced control system that can continually monitor the temperature of the motors and bearings, and by leakage detectors that can sense the presence of water in the motor chamber, junction box or oil chamber.

“We know that the abrasive conditions at our site are tough on pumps. Sulzer’s dewatering pumps have, however, been running nonstop at two rain stations, without any maintenance since they were installed four years ago” says Cesar Carraro, Section Manager at Anglo American. “Sulzer has been able to meet our reliability expectations, and they have become a valuable partner in the project, with a strong commitment to service, support and innovation.”

Follow Sulzer Industry on LinkedIn

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and purification technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Flow Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Comments